Bandsaw, Horizontal - Hafco BS-7DS

| Aliases | - |

| Other References | |

| Official Maintainer | Phil Juric |

Current Status

Working

Machine is working as expected.

Usage

This machine requires induction to use.

Book an induction in Eventbrite.

https://www.eventbrite.com/cc/metalshop-inductions-804979

This machine is a part of the Drill Press, Linishers and Vertical bandsaw induction.

Personal Protective Equipment

| Required |  | Always wear AS/NZS 1337.1 compliant safety glasses while operating this machine. |

| Required |  | Enclosed shoes are required, no open sandals, thongs etc |

| Required |  | Restrain hair while operating machine |

| Prohibited |  | Loose clothing and jewellery not to be worn while operating this machine. |

| Recommended |  | We recommend hearing protection. |

| Warning |  | Entanglement hazard present while wearing gloves. |

| Maintenance |  | Disconnect power to the machine before performing maintenance, including wheel changes |

Machine Specifications

| Name | Value |

|---|---|

| Motor Power | 750W 240V |

| Blade Size | 2362x19x0.8 |

| Rectangular Capacity @ 90° | 215mm X 178mm |

| Rectangular Capacity @ 45° | 140mm x 85mm |

| Blade Speeds | 24, 41, 61, 82mpm |

| Mitre Angle Limits | -45°, +45° |

| Weight | 165kg |

Documents

Supplier

- Hare & Forbes MachineryHouse

- P 07 3715 2200

Known Issues

| Date | Description | Workaround | Proposed Remediation |

|---|---|---|---|

| 9/8/2022 | Main On/Off Sitch failure | None | Replace the switch - Electrician required |

| 9/8/2022 | Interlock Failure | Interlock has been disabled | Replace the interlock microprocessor board |

Modifications / Repair History

| Date | Modified By | Description | Remediation | Cost |

|---|---|---|---|---|

| 17/11/2020 | Eris Ryan | Fletcher Barnes had breaker tripping | Tested fine. 10M Ohm to earth. Put back into service. | $0 |

| 08/12/2020 | Eris Ryan | Blade not moving | Blade had come loose, reattached and tightened | $0 |

| 08/12/2020 | Ryan Marple | All bandsaw blades dull | Purchased 2 new bi-metal blades | $110 |

| 08/12/2020 | Ryan Marple | Fasteners holding cover require different tools to open | Replaced fasteners with wing screws | $20 |

| 04/01/2022 | Dave Seff | Repaired water damaged interlock | Replaced contactor | $70 |

Accessories

| Image | Category | Accessory Name & Notes | Location | Buy from |

|---|---|---|---|---|

Consumables & Running Costs

| Image | Category | Accessory Name & Notes | Location | Buy from |

|---|---|---|---|---|

| Coolant | Penrite Soluble Oil Mixed with water to create cutting fluid. | Stored in metal shop chemical cabinet | Penrite Soluble Oil 20L Drum |

| Blade | 2362 x 19 x 0.80mm Bandsaw Blade Bi-metal blades are preferred due to their longer lifespan than regular blades. The preferred blade is bi-metal 6-10TPI. | Hung above metal shop chemical cabinet | 6-10TPI Bi-Metal Blade (Preferred) 4-6TPI Bi-Metal Blade 10-14TPI Bi-Metal Blade 6TPI Carbon Steel 8TPI Carbon Steel 10TPI Carbon Steel 14TPI Carbon Steel |

Maintenance

| Interval | Task |

|---|---|

| Daily | Top up coolant tank with tap water |

| Weekly | Oil vice lead screw and machined surfaces |

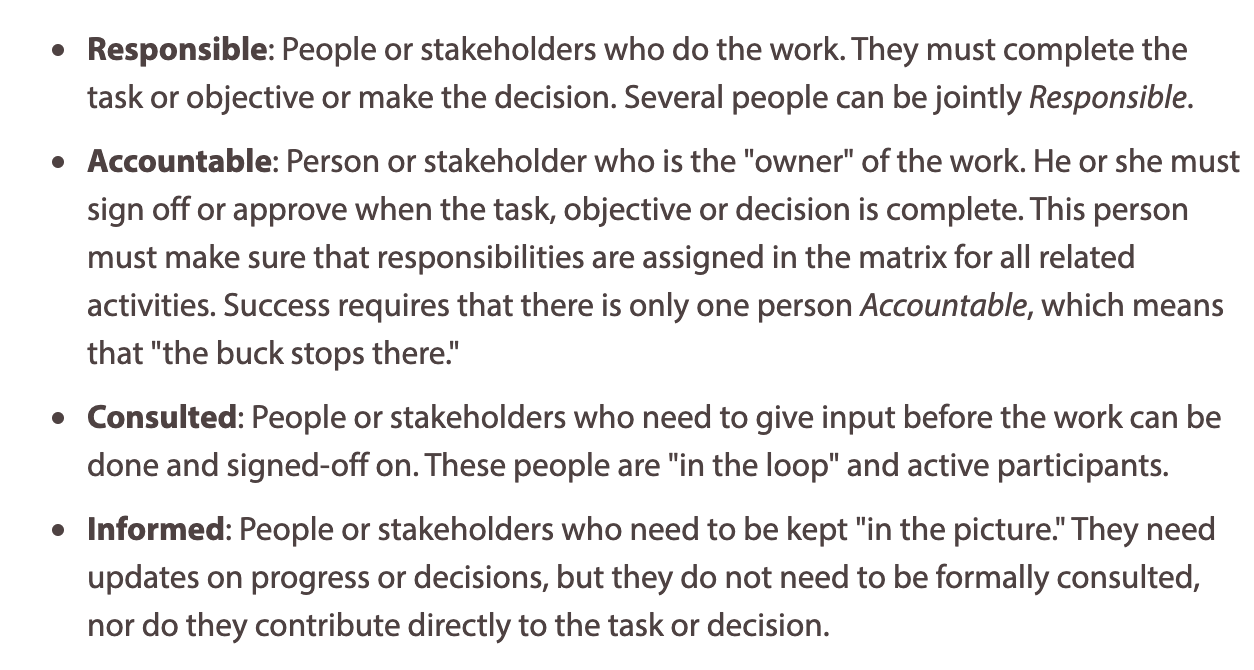

RACI

| Task / Action | Executive | Cause Leader Cause Team | Named Maintainer | Trainers | Cause | Membership | Implementer |

|---|---|---|---|---|---|---|---|

| Modification and Repairs | - | AC | C | I | I | I | R |

| Induction changes | C | RACI | RC | I | I | I | R |

| Daily Maintenance | - | - | I | - | - | - | R |

| Weekly Maintenance | - | - | RAI | - | - | - | R |

| Changing Blade | - | - | - | - | - | - | R |

| Setting cut angle | - | - | - | - | - | - | R |

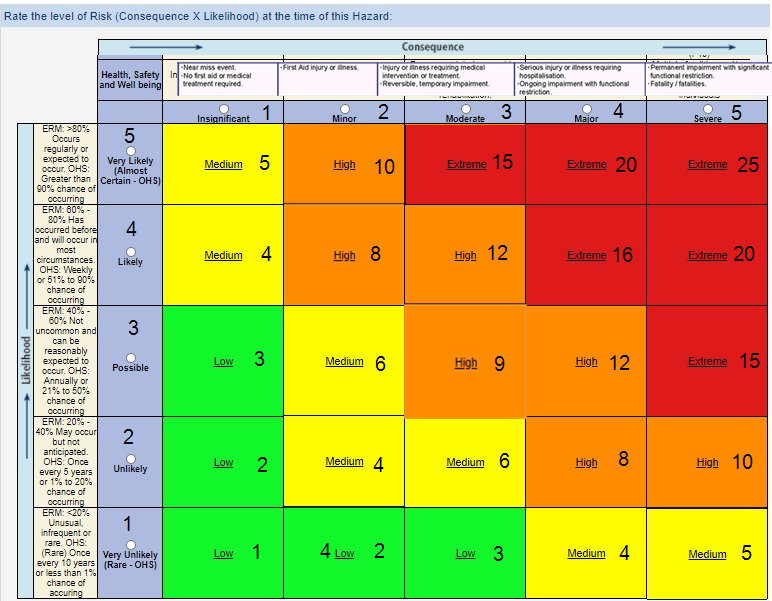

Risk Matrix and Mitigation

| Ref / ID | Pre-Mitigation | Mitigations / Warnings / Remedies | Post Mitigation | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Risk | Risk Severity | Risk Likelyhood | Risk Level | Risk Severity | Risk Likelyhood | Risk Level | Acceptable to Proceed | ||

| 0001 | Death | Severe | Possible | 15 | Induction to train users in correct usage. | Severe | Very Unlikely | 5 | Yes |

| 0002 | Electric Shock | Major | Unlikely | 8 | Induction to train users in correct usage. Ensure power cables are properly connected and off the floor. Cables are tested and tagged and inspected for damage. | Minor | Very Unlikely | 2 | Yes |

| 0003 | Noise | Moderate | Likely | 12 | Train users to wear hearing protection. | Insignificant | Unlikely | 2 | Yes |

| 0004 | Tripping Hazard | Moderate | Possible | 9 | Train users to maintain a clean working area. Keep all cables off the ground and secured out of the way. | Insignificant | Unlikely | 2 | Yes |

| 0005 | Insufficient Lighting | Minor | Possible | 6 | Turn on shop lights. Open metal-shop doors for natural lighting. | Insignificant | Unlikely | 2 | Yes |

| 0006 | Entanglement | Major | Possible | 12 | Induction to train users in correct usage. Remove any possible entanglement items such as long sleeves, gloves, watches, jewellery, etc. Tie back long hair. | Minor | Unlikely | 4 | Yes |

| 0007 | Slip | Major | Possible | 12 | Induction to train users in correct usage. Train users in correct use of coolant to avoid spilling on the floor. | Minor | Unlikely | 4 | Yes |

| 0008 | Respiratory/Skin Irritation | Moderate | Unlikely | 6 | Induction to train users in correct usage. Train users in the risks related to metalworking fluids. | Minor | Unlikely | 4 | Yes |

| 0009 | Inhaliation of Fumes | Moderate | Possible | 9 | Induction to train users in correct usage. Open metal-shop door to allow ventilation. Fans are provided top assist in ventilation. Train users to use the appropriate type and volume of coolant. Require use of appropriate PPE. | Minor | Unlikely | 4 | Yes |

| 0010 | Laceration/Dismemberment | Major | Possible | 12 | Induction to train users in correct usage. Train users to keep clear of the cutting tool and the part. Require that the cutting tool is securely fixed (in the quick change tool-post or tail-stock). Require use of appropriate PPE. | Minor | Unlikely | 4 | Yes |

| 0011 | Burn from workpiece | Moderate | Possible | 9 | Induction to train users in correct usage. Allow parts to cool after cutting. Train users to ensure adequate coolant is used. Require assessing workpiece temperature before handling. | Insignificant | Unlikely | 2 | Yes |

Decision Register

| Ref / ID | Decision Details | Impact | Proposed Date | Proposed By | Status | Approved By | Date | Resulting Actions and Comments |

|---|