Table of Contents

Ledacraft PS-12 305mm Sliding Panel Table Saw

| Aliases | “the table saw”, “PS12” |

| Other References | |

| Official Maintainer | Ale Moré |

Current Status

Usable

The scribing blade mechanism has been removed for servicing.

Joshua 13/08/20

Usage

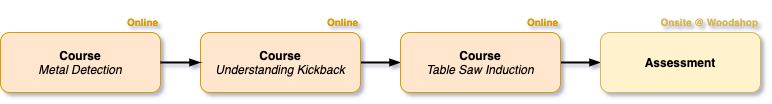

Induction

This machine requires induction.

Induction process is completion of online courses and a 15min in person physical evaluation.

- ENROLL in the Metal Detection Course. 100% required pass.

- ENROLL in the Understanding Kickback Course. 100% required pass.

- ENROLL in the Table Saw Induction. 100% required pass.

- BOOK a time to complete your in person assessment of competency

Nominated supervisors:- Joshua Hogendorn

- Ale More

Guidelines

How to use the microadjustment

Note: To have a better understanding of this technique, you might want to check the modifications that we made to the endstops.

- With the swivel hard against the stop, set the stop to a dimension that's smaller than the nominal dimension by an amount that you think is suitable (E.g. how much macro-adjustment you need).

- Back the swivel paying attention to the gauge on the micro-adjustment knob and go pass the nominal dimension.

- Take a cut, measure using the method of your preference and adjust accordingly.

Recommended PPE

| Recommended |  | The saw is loud, we recommend hearing protection. |

| Mandatory |  | Please wear goggles or a face shield |

| Recommended |  | We recommend the use of a respirator |

| Recommended |  | Use all available guards |

| Recommended |  | Please keep the shop door closed when using the table saw to limit kickback projectile scope |

| Required |  | Remove all jewelry and watches |

| Required |  | Enclosed shoes are required, no open sandals, thongs etc |

| Required |  | Dust extraction must be used at all times during operation |

| Warning |  | Gloves are PPE against your material (splinters, resin etc) but are hazardous around the saw. Please carefully evaluate your use of gloves |

| Maintenance |  | Disconnect power to the saw before performing maintenance, including blade changes |

Machine Specifications

| Name | Value |

|---|---|

| Nominal Blade Size | 305mm |

| Max Blade Size | 315mm |

| Dimensions of sliding table | 1600 mm x 270 mm |

| Diameter of scoring saw blade | 90 mm |

| Saw blade assembly tilting | 0º to 45º |

| Maximum depth of cut @ 90º | 100 mm |

| Maximum depth of cut @ 45º | 80 mm |

| Motor driving both saw blades (single phase) | 3.0 hp |

| Maximum width of cut on rip fence | 1250 mm |

Documents

Manufacturer

Ledacraft

- E sales@ledamachinery.com.au

- P 08 7127 7730

Reseller

- Lance Dargusch

- Darcy Glister Agencies

- E lance@ledamachinery.com.au

- M 0408 765 922

Known Identical Models

Known Issues

| Date | Description | Workaround | Proposed Remediation |

|---|---|---|---|

| - | Blade change pin bending over time | Still works until it breaks | Lathe replacement from tool steel |

| - | Blade plate is slowly deforming | Still works | Manufacturer replacement or cnc replacement |

| - | Sliding fence has slop at main pivot being loose in extrusion | Saw has to be manually tuned with 5 cut method for high accuracy cuts. | Machine uhmw spacer to reduce slop |

| - | Blade guard damaged by reseller demonstration, design deemed unsafe due to catching material. | Blade guard removed | New guard to be CAD and laser cut |

| - | Slide is not smooth operating | - | - |

| - | Sliding fence angle gauge stickers worn off | Measure angle manually with other tools | Replacements CAD and laser cut/etched in <1mm stainless steel |

| - | Arbour thread is not clean and hard to manage | - | - |

| - | Rise and fall lock never worked | lever removed | - |

| - | Scribing blade bearing is totally seized, stopping the saw operating | Part is currently removed | needs new bearing or total manufacturer part replacement |

| - | People treat the handles that secure the sliding table to the machine as adjustable points when trying to operate the machine. This results in the sliding table becoming uncalibrated. | none | Replace handles with bolts |

Modifications / Repair History

| Date | Modified By | Description | Remediation | Cost |

|---|---|---|---|---|

| - | Joshua H | Rise/fall and angle handles fell apart | machined some adapters and used a surpus handle from the A331 | <$5 |

| - | Joshua H | Ratcheting handles that secure the sliding table extension broke | replaced by better ones from ebay | ~$40 |

| - | Joshua H | Angle indication on front inaccurate | shimmed with washers to be accurate | - |

| - | Joshua H | Screw for changing scribing blade height was inappropriate and crashing with table surface, and wearing due to flathead design. | Replaced with appropriate grub screw | <$5 |

| - | Joshua H | 90º fence stop for sliding table fence deemed unusable | replacement mechanism designed in CAD, machined by members and installed. | - |

| - | Craig Hudson | Riving knife always higher than blade, stopping joinery cuts. | Riving knife modified to allow for correct height for joinery | - |

| - | Joshua H | Sliding table fence scale hard to make accurate | Stop at end of sliding table fence replaced with wooden block tuned to make the scale on fence accurate | - |

| - | Joshua H | Sliding table fence angle lock bolt stretched and worn by overtightening | replaced by parts from jig kit | - |

| - | Joshua H | Sliding table clamp post unhardened and raising burrs | part hardened by forge cause | - |

| - | Joshua H & Ian Redmond | Rise and fall gear/worm totally worn and failed. | Replacement parts ordered but incorrect due to machine revision. Fix found by rotating gear 180º to unworn section | ~$150 |

| - | Ryan Marple & Ale Moré | Rise and fall gear/worm totally worn and failed. | Parts were milled, specifically, holes were slotted to allow the installation of a different size worm wheel. | - |

| 14/02/2021 | Ryan Marple & Ale Moré | The stops couldn't be calibrated with ease | Crosscut endstops were modified with an adjustable bullseye | - |

| 15/01/2022 | Ale Moré | Planned maintenance | Change the arbour bearings |

Crosscut Fence Stops

The crosscut fence stops have been modified to be more accurate and easily corrected if needed. By design, the modification doesn't take into account any adjustments you make using the micro-adjustment. In other words, the bullseye is 100% accurate only when the swivel arm is hard against the fixed part of the stop. Having said that, it doesn't mean that you can't use the micro-adjustment, you just need to plan ahead (which is commonly the case with micro-adjustments).

Accessories

| Image | Category | Accessory Name & Notes | Location | Buy from |

|---|---|---|---|---|

| Sled | Mitre Fence for sliding table The mitre fence that fits the sliding table | Bottom drawer of accessories cabinet | ||

| Sled | Mitre Fence for main table The mitre fence that fits the main table | Bottom drawer of accessories cabinet | |

| Material Handling | Sheet Clamp This is used with sheet goods to clamp them against the sliding table fence, ie an extra set of hands | Bottom drawer of accessories cabinet | ||

| Material Handling | Featherboards Extra hands to help you keep material constrained | Fourth drawer of accessories cabinet | |

| Safety | Push Sticks Many types and sizes and shapes, use these to get distance from the blade | Top drawer of accessories cabinet | Carbatec |

| Maintenance | Blade Change Spanners 1 Arbour pin, 3 Spanners, for main blade, scribing blade, riving knife. Not to be removed from workshop | Second drawer of accessories cabinet | |

| Measuring | Engineers Square To check for 90º | Third Drawer of accessories cabinet | |

| Measuring | Depth Gauge For precision height setting | Third Drawer of accessories cabinet | |

| Measuring | Digital Protractor Precision angle setting | Third Drawer of accessories cabinet | |

| Measuring | Dial Gauge & Arm For micro adjustments to fences, alignments, and general maintenance | Third Drawer of accessories cabinet | |

| Safety | Fence Offset Allows the user to create a safety zone past the blade | Fourth drawer of accessories cabinet | |

| Safety | Sacrificial Fence Required when operating the blade within 10cm of fence. Also has specific clamps for use with it. | Fourth drawer of accessories cabinet |

Consumables & Running Costs

| Image | Category | Accessory Name & Notes | Location | Buy from |

|---|---|---|---|---|

| Blades | General Purpose Blade 305mm ATB 40T 10º | Sawblade Holder | |

| Blades | Joinery Blade 305mm FTG 40T 10º | Sawblade Holder | Rigid Carbide Special Order |

| Blades | Rip Blade 305mm ATB 24T 15º | Sawblade Holder | |

| Blades | Crosscut Blade 305mm ATB 60T 10º | Sawblade Holder | |

| Blades | Aluminium & Plastics Blade 305mm TCG 80T 0º | Sawblade Holder | |

| Blades | Scribing Blade –mm Conical 60T 10º | Sawblade Holder |

Maintenance

| Interval | Task |

|---|---|

| Quarterly | Assess and send blades for sharpening |

| Monthly | Assess sliding table height and angle relative to main table and blade. Nominal 0.05-0.1mm proud of main table, parallel to blade. |

Sharpening log

| Date | Blade | Notes |

|---|---|---|

| 13/09/2021 | TCG Acrylic | Sharpen by Brisbane Saw Services |

| 13/09/2021 | TCG (Laminates) | Sharpen by Brisbane Saw Services |

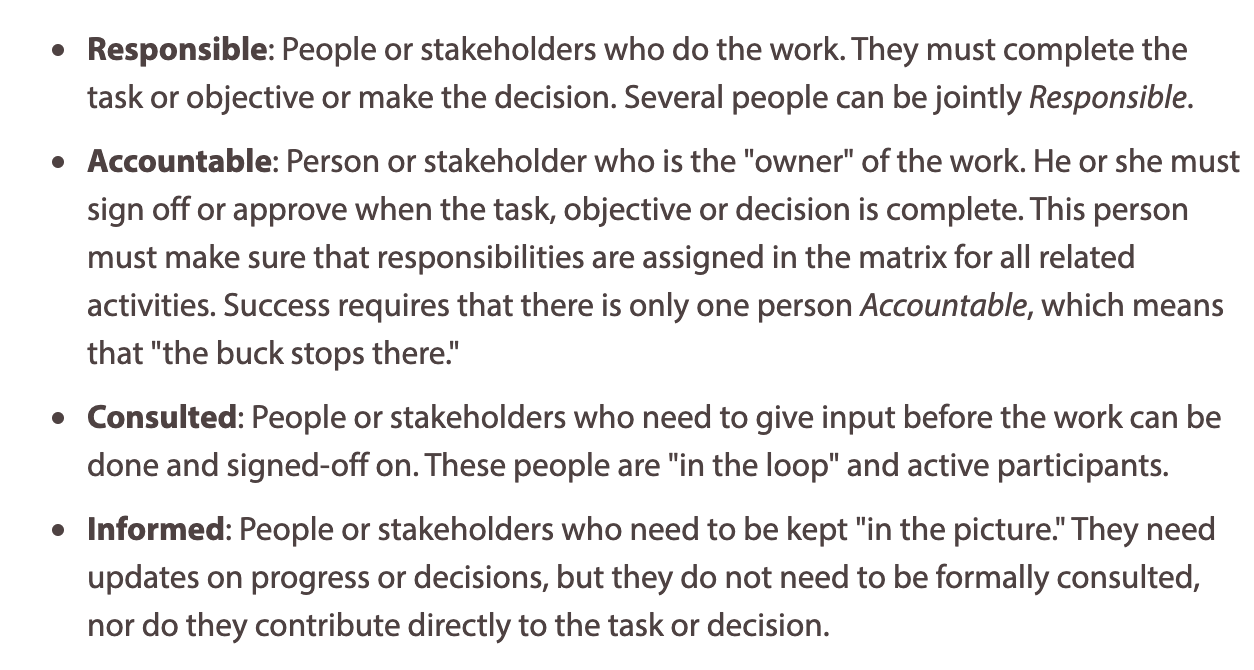

RACI

| Task / Action | Executive | Cause Leader Cause Team | Named Maintainer | Trainers | Cause | Membership | Implementer |

|---|---|---|---|---|---|---|---|

| Modification and Repairs | - | AC | C | I | I | I | R |

| Induction changes | C | RACI | RC | I | I | I | R |

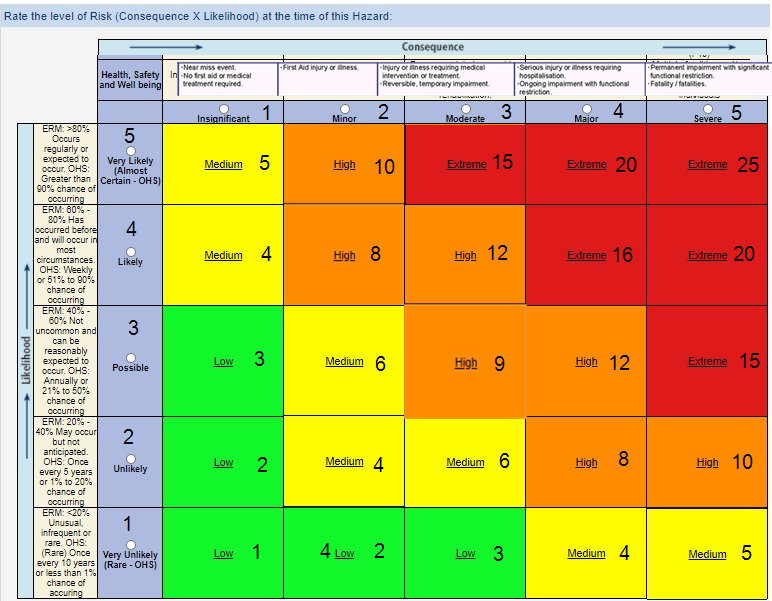

Risk Matrix and Mitigation

| Ref / ID | Pre-Mitigation | Mitigations / Warnings / Remedies | Post Mitigation | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Risk | Risk Severity | Risk Likelyhood | Risk Level | Risk Severity | Risk Likelyhood | Risk Level | Acceptable to Proceed | ||

| 0001 | Amputation from improper usage | Intolerable | Probable | 11 | Induction to train users in correct usage Provision of push devices Safety accessories | Low | Improbable | 1 | |

| 0002 | Damage to machine from incorrect setup | Undesirable | Probable | 9 | Induction to train users in correct usage Rule of 10 Sacrificial Fence Replaceable high risk parts | Low | Improbable | 1 | |

Decision Register

| Ref / ID | Decision Details | Impact | Proposed Date | Proposed By | Status | Approved By | Date | Resulting Actions and Comments |

|---|---|---|---|---|---|---|---|---|

| 0000 | Example decision | Provides an example | 08/08/20 | JH | Approved | JH | 08/08/20 | A line was put in the register |