Kiln

| Aliases | “Pottery Kiln” “large kiln” | |

| Official Maintainer | Eris Ryan |

Current Status

Maintenance

Machine is undergoing upgrades and can't be used.

Usage

This machine requires induction unless you are having an inducted person fire it for you.

Induction process is doing the theory courses then being shown how to pack and program the machine at HSBNE by the responsible person.

- Kiln basics that apply to all kiln use at HSBNE. Training and assessment online. ADD LINK

- Specific training course for the large pottery kiln. Training and assessment online. ADD LINK

- Being shown on the kiln how to pack and use the kiln, where the kiln shelves are kept and how to tidy up afterwards. Contact responsible person to set a time.

Guidelines

This kiln is to be used for pottery or approved (eg PLA, wax) large casting “burnouts” ONLY. Under no circumstances is it to have steel or any metal added to it (except aluminum trays to catch “burnouts” up to 400°C). It is NOT a heat treating oven.

Under no circumstances are you to leave the space while the kiln is running without another inducted person agreeing to take over for you and stay.

Under no circumstances is the kiln to be used with a “heating profile” that is not approved by the responsible person. Do not add new profiles without prior approval.

Unless it's an emergency, the kiln is not to be switched off above 600°C as it needs time to cool slowly above that temperature (this is in the “heating profile”). Heating/cooling too fast will not only damage the bricks inside the kiln walls, it may ruin your/other people's craft work within.

Do not store flammable materials near the kiln such as wood, gas bottles and lubricating grease.

Recommended PPE

| Recommended |  | We recommend heat gloves. |

| Recommended |  | Please wear goggles or a face shield when mixing casting powders |

| Recommended |  | We recommend the use of a respirator when mixing casting powders |

| Required |  | Enclosed shoes are required, no open sandals, thongs etc |

| Maintenance |  | Disconnect power to the kiln before performing maintenance, including opening lid. |

Machine Specifications

| Name | Value |

|---|---|

| Max Temperature | 1250°C |

| Internal Size | 600mmLx900mmWx450mmD |

| Power Use | 19kW continuous (depends on use) 3 Phase 240VAC |

Documents

As this modified machine is from 1982 and no longer manufactured no manual is available. General controls for large kilns and the “picoReflow” Github can be used however. https://apollo.open-resource.org/mission:resources:picoreflow https://github.com/HSBNE/picoReflow

Manufacturer

Manufacturer

- E info@tetlow.com.au

- P +61 (0)3 8545 8296

Reseller/Maintenance

- Walker Ceramics

- E orders@walkerceramics.com.au

- Tel: 1800 692 529

Known Identical Models

Known Issues

| Date | Description | Workaround | Proposed Remediation |

|---|---|---|---|

| 03/10/2020 | Element wearing out | keep kiln below 1200°C until elements replaced - approved by vote 15/09/2020 | Eris to replace elements Electrician to approve |

Modifications / Repair History

| Date | Modified By | Description | Remediation | Cost |

|---|---|---|---|---|

| 01/01/2018 | Eris | Kiln dried, cleaned, patched, rewired with SSR and extra safety devices | in series are lid switch, second controller to limit temp to 1250°C, 24vdc plugpack | ~$200 |

| 03/10/2020 | Eris | Waited for kiln to dry and be tested electrically and test fired Relined 3/10/20 | testfired to 200°C 06/10/2020 8MΩ to ground. |

in series are lid switch, second controller to limit temp to 1250°C, 24vdc plugpack. | Approved by vote ~$200 |

Accessories

| Image | Category | Accessory Name & Notes | Location | Buy from |

|---|---|---|---|---|

| Furniture / Shelves | Kiln shelves, kiln posts, kiln tubes. Used to separate pottery during firing | Inside kiln or in hardstand container “A” | https://www.potterysuppliesonline.com.au/48/101/electric-kilns/electric-kilns/kiln-furniture.html?limit=12&start=12 |

Consumables & Running Costs

| Image | Category | Accessory Name & Notes | Location | Buy from |

|---|---|---|---|---|

| You can't see electrons. | Billed to HSBNE | Power meter records power used, note difference before and after firing. Please donate this multiplied by $0.25 per kWhr | The power meter is located at the bottom of the control panel. | Energex, AGL, Zeus. |

| tools:craftpunk:nichrome_wire_roll.jpg | Long term maintenance | Every few years of heavy use will need ~$2000 worth of wire to be replaced. 1.8mmx180 metres 16mm diameter coils 9ohm per phase | http://shop.walkerceramics.com.au/Kilns-_and_-Accessories/1770-ELEMENT-WIRE/pl.php | Walker ceramics, Alibaba. |

Maintenance

| Interval | Task |

|---|---|

| Annual | Check element resistance is not higher than 9 Ohms per phase, patch up cracks with kiln cement/fire putty, clear furniture and vacuum out kiln of debris. |

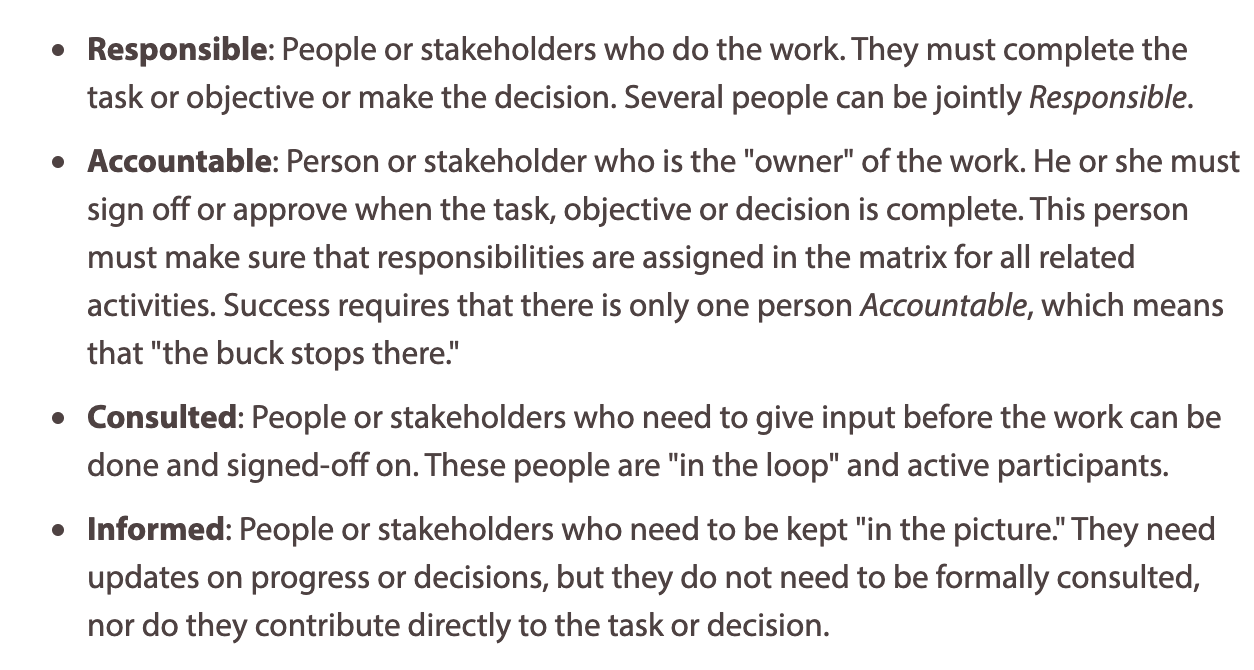

RACI

PLACEHOLDER A RACI is an important documentation process to let people know what ACTIONS can happen, and who needs to be Responsible, Accountable, Consulted and Informed for each ACTION. Delete this line.

| Task / Action | Executive | Cause Leader Cause Team | Named Maintainer | Trainers | Cause | Membership | Implementer |

|---|---|---|---|---|---|---|---|

| Modification and Repairs | - | AC | C | I | I | I | R |

| Induction changes | C | RACI | RC | I | I | I | R |

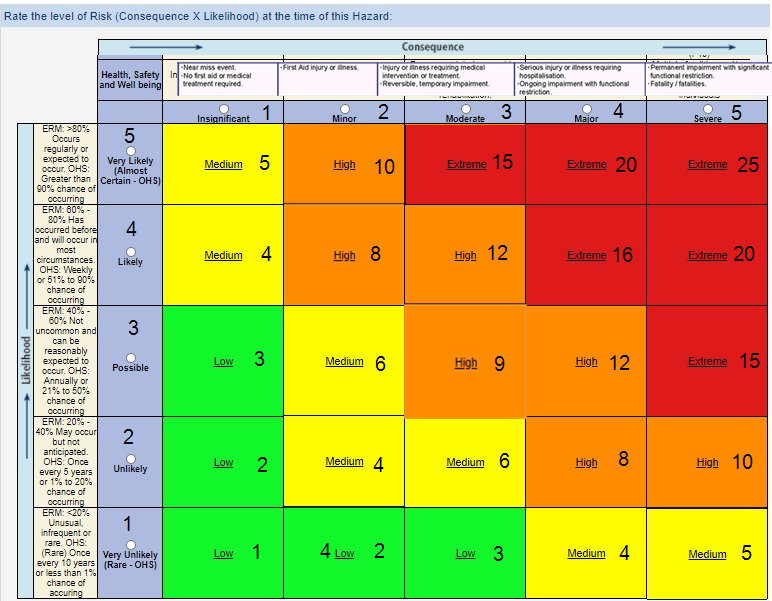

Risk Matrix and Mitigation

PLACEHOLDER: Risk assessment is important to ensure we are making tools available to members in a responsible fashion. Please make every effort to do a reasonable risk assessment. If there is a safety incident with the tool, please redo a risk assessment and add it to the table.

| Ref / ID | Pre-Mitigation | Mitigations / Warnings / Remedies | Post Mitigation | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Risk | Risk Severity | Risk Likelyhood | Risk Level | Risk Severity | Risk Likelyhood | Risk Level | Acceptable to Proceed | ||

| 0001 | DEATH / Shock | Intolerable | possible | 9 | Induction to train users in correct usage, lid interlock | Low | Improbable | 1 | Yes |

| Severe Burns | Intolerable | Probable | 11 | Induction to train in correct usage, Signage when firing for others, kiln gloves | Low | Improbable | 1 | Yes | |

| Switchboard Trip | Low/Nusance | possible | 3 | Induction training on 3 phase plugs, not touching kiln breaker settings | Low | unlikley | 1 | Yes | |

Decision Register

PLACEHOLDER: A decision register is for general documentation when some decision is made regarding the tool. To change its location, mode of operation, to buy an accessory, to replace something, to change how it operates etc. Delete this line.

| Ref / ID | Decision Details | Impact | Proposed Date | Proposed By | Status | Approved By | Date | Resulting Actions and Comments |

|---|---|---|---|---|---|---|---|---|

| 0000 | Maintenance/Upgrade | safety, allows automation, remote monitoring. | 15/09/20 | ER | Approved | Vote | 15/09/2020 | ~$2,000 budget for nichrome wire, fireclay patch job and PicoReflow upgrade. |