Redsail X700 Laser Cutter

| Aliases | “LITTLE RED”, “RED LASER CUTTER” |

| Other References | |

| Official Maintainer | Aaron 'Crofty' Bycroft, Scott 'Siridar' Wilson |

Current Status

Usable

Machine is usable, but requires induction.

Usage

This machine requires induction or supervision to use.

Induction

In order to get inducted on the laser cutter, you need to go to the following Eventbrite event and book a place for yourself on one of the available dates.

Inductions happen fortnightly.

Things to keep in mind

- Inductions signups close 3 days before the event start. This allows volunteers to organise their life.

- If no one has signed up for the date before it closes, the induction is cancelled.

- If the induction is on (because people signed up in time), but the time has passed, you can always ask in discord if you can get into the induction.

Not Familiar with Lightburn?

You can find all sorts of information on LightBurn Software Documentation

You can watch all the tutorials HERE

Induction booklet

This is the documentation we use to give the inductions. It's always being updated and you can always find the latest version here.

Guidelines

- When operating this machine, under absolutely NO circumstances must it be left unattended.

- If anything goes wrong, your first port of call is to always bang the big, red Emergency Stop button. It's there for a reason, don't be afraid of using it. Even the resident laser cutter experts have to hit it every so often, because things happen.

- Try to avoid staring at the cutting point. We know it's pretty & oh-so-mesmerising to watch, but it's very bright & you'll end up with temporary spots in your vision.

- Only cut approved materials that are known to be safe. If you disobey this rule, you will create toxic fumes potent enough to put you in hospital and/or you'll generate gaseous forms of very strong acids which will literally eat away & dissolve the machine's insides.

- The nearest fire extinguisher is by the door to this room. Don't use the fire extinguisher unless it's necessary, but if the situation calls for it don't hesitate for one second because a fire will spread very quickly inside the machine. Having to thoroughly clean & align a laser cutter is a pain but it's far better than having to replace a burnt-out shell of an ex laser cutter.

Recommended PPE

| Recommended |  | Please wear goggles or a face shield |

| Maintenance |  | Disconnect power to the device before performing maintenance, including mirror adjustments |

Machine Specifications

| Name | Value |

|---|---|

| Color | Red and Black |

| Bed Size | ~700mm x ~500mm |

| Power | 60W power supply, 80W rated glass tube |

| Wavelength | CO2 infra-red 10.6µm |

| Max Speed | 1000mm/s |

| Max Engraving Speed | 100mm/s |

| Max Resolution | 10000dpi |

| Modes of operation | Vector cutting, Vector marking (outline), Vector engraving (Raster fill), 3D gradient Raster fill engraving |

| Controller Board | Ruida RDC6432 |

| Software | Inkscape or Adobe Illustrator for modelling, LightBurn to operate laser |

| Z Axis Clearance | ~200mm |

Documents

Chiller Instruction Manual Download

Lightburn Instruction Manual (09/09/2021) Download

What materials can be cut / engraved

| Material | Notes | Warning |

|---|---|---|

| Acrylic/Plexiglass/Perspex/Lucite/Acrylite | ||

| Most woods | Avoid oily and resinous woods | Oily/resinous species might catch fire and dirty the laser optics |

| MDF | You may experience a higher amount of charring | |

| Plywood | Get plywood that's laser safe | Don’t use marine ply. Doesn't cut nice, burnt edges. High fire risk |

| Paper/cardboard | Be careful, watch it closely. Fire risk | |

| Cork | Quality of the cut depends on the thickness and quality of the cork | Engineered cork has a lot of glue in it, and may not cut as well. |

| Cloth/cotton/felt | Only used natural fiber fabrics | |

| Natural leather/suede/nubuck | Can be cut if thin, or engraved at any thickness | Do no use artificial leather, or chrome-tanned natural leather |

| Ceramic tiles, stone, marble, granite and similar | Engraving only | Must be covered in painter's tape first |

| Glass | Engraving only | Must be covered in painter's tape first. Be careful with the glass dust |

| Polyester (PES), Polyethylene (PE), Polyurethane (PUR) FOAM | Check MSDS from supplier | Do not use Polystyrene or PolyPropylene foam |

What materials can’t be cut / engraved

Some materials when they are cut can catch fire really easily and some of them release harmful dust and gases that can damage the machine and even endanger yourself. As well some of them cut poorly leaving gooey residue behind. These are the reasons why the following material can’t be cut.

| Material | Notes | Warning |

|---|---|---|

| Metal | It simply doesn’t cut or engrave any metal of any thickness. | |

| Any materials containing halogens (fluorine, chlorine, bromine, iodine and astatine), epoxy or phenolic resins | Contains chlorine and other harmful chemicals that are released when cut | Toxic fumes |

| PVC | Contains chlorine | Toxic fumes |

| Vinyl | Contains chlorine | Toxic fumes |

| Artificial leather, pleather, moleskine etc, as well as chrome-tanned natural leather | Contains chlorine | Toxic fumes |

| Polycarbonate/Lexan/Makrolon | Cuts poorly, melts and discolours, almost impossible to cut | Catches on fire |

| Polystyrene, including Polystyrene foam | This is the #1 material that causes laser fires | Catches on fire |

| Nylon | Melts and burns | Catches on fire |

| ABS | Melts and burns | Produces cyanide gas with high fire risk. |

| HDPE (Milk bottle plastic) | Melts | Catches on fire |

| Epoxies such as those found in resins or glues, including epoxy-coated items | Toxic fumes | |

| Fibreglass and carbon fibre | Thin carbon fiber mat can be cut, with some fraying - but not when coated. | Toxic fumes |

| Cutting printed circuit boards (FR4 and other material types) | Toxic fumes | |

| PTFE/Teflon | Produces hydrofluoric acid | Toxic fumes |

| Food of any description |

Known Issues

| Date | Description | Workaround | Proposed Remediation |

|---|---|---|---|

| 06/04/2021 | PLACEHOLDER | PLACEHOLDER | PLACEHOLDER |

Modifications / Repair History

| Date | Modified By | Description | Remediation | Cost |

|---|---|---|---|---|

| 11/10/2021 | Cameron Payne | Ruida Controller Ordered Again (First considered lost) | https://www.dhl.com/au-en/home/tracking/tracking-express.html?submit=1&tracking-id=9843808085 | $429.69 |

| 31/08/2021 | Ale Moré and Cameron Payne | Mirrors and lens cleaned + Aligned | All three mirrors and lens cleaned and Aligned | |

| 31/08/2021 | Ale Moré and Cameron Payne | Airline Replaced Again | Airline replaced again with PU 6mm (Nylon was too hard and causing issues with head movement) | $22 |

| 09/08/2021 | Cameron Payne | Ruida Controller Ordered | https://m.aftership.com/ubi-logistics/AUS223940801512 | $321.64 |

| 09/08/2021 | Ale Moré and Cameron Payne | Airline Replaced | Airline replaced with Nylon 6mm | Free MetalShop |

| 23/02/2021 | Brendan Halliday | Laser Mirrors Realigned | Laser mirrors were aligned correctly. | Some sanity, |

| 04/09/2020 | Mike Ando | Mirrors and lens cleaned | All three mirrors and lens cleaned | |

| 03/03/2020 | Michael King and Jarod Saunders | Extraction fan ducting patched | Extraction fan ducting patched | |

| 03/03/2020 | Mike Ando | Second and third mirrors and lens cleaned | Second and third mirrors and lens cleaned | |

| 23/02/2020 | Drew Spriggs | Compressor and extractor fan fixed | Compressor auto drain replaced, compressor reed valved replaced, extractor fan start capacitor replaced by qualified electrician | |

| 07/02/2020 | Drew Spriggs | Lens cleaned | Lens cleaned | |

| 05/01/2020 | Power connector replaced. | Power connector replaced. |

Accessories

| Image | Category | Accessory Name & Notes | Location | Buy from |

|---|---|---|---|---|

| Cleaning | Wipes for cleaning supports and internals | On machine, in store room | https://www.lekura.com.au/products/hospital-plus%e2%84%a2-triple-pack-surface-disinfectant-240-wipes |

Consumables & Running Costs

Maintenance

Caution – use of controls, adjustments, performance of procedures other than those specified here in may result in hazardous laser radiation exposure. Before starting cleaning or maintenance work always switch off the device at the interlock level. Always keep the system clean, as flammable parts in the working area or exhaust area rise the fire hazard.

The cleaning interval strongly depends on the material that is being processed and the operating time of the device. Please bear in mind that only a clean machine guarantees optimal performance and reduces our service costs.

Cleaning the Laser Machine

| Interval | Task |

|---|---|

| Daily | Thoroughly remove all loose dirt particles and deposits in the interior of the machine |

| Daily | Clean out anything under the bed with the dustpan |

| Daily | Wipe down all the bars, the side & rear walls, the Aluminium rails, the underneath area. |

| Daily | Clean the viewing window with a cotton cloth. Do not use paper towels as they could scratch the acrylic |

| Daily | Brush the air extraction grill if necessary |

| Daily | Keep the Digifab room as free from dust as possible, vacuum it if it has not been done within the last fortnight |

| PLACEHOLDER Pick one: Daily/Weekly/Monthly/Quarterly/Biannual/Annual | PLACEHOLDER Description of maintenance task and any relevant parameters |

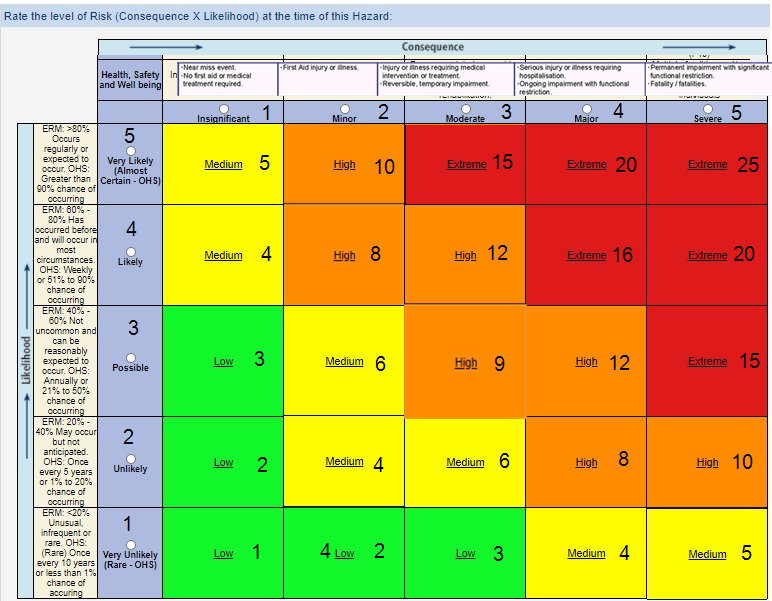

Risk Matrix and Mitigation

Risk assessment is important to ensure we are making tools available to members in a responsible fashion. Please make every effort to do a reasonable risk assessment. If there is a safety incident with the tool, please redo a risk assessment and add it to the table.

| Ref / ID | Pre-Mitigation | Mitigations / Warnings / Remedies | Post Mitigation | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Risk | Risk Severity | Risk Likelyhood | Risk Level | Risk Severity | Risk Likelyhood | Risk Level | Acceptable to Proceed | ||

| 0001 | Death | Intolerable | Possible | 1 | Induction to train users in correct usage | Low | Improbable | 1 | Yes |

| 0002 | Crushing Injury | Intolerable | Possible | 4 | Induction to train users. Warning signage. Emergency Stop buttons | Low | Improbable | 1 | Yes |

| 0003 | Burns | Undesirable | Possible | 4 | Induction to train users. | Low | Improbable | 1 | Yes |

| 0004 | Trips | Undesirable | Possible | 4 | Induction to train users. | Low | Improbable | 1 | Yes |

| 0005 | Spilled Fluid | Undesirable | Possible | 4 | Induction to train users. | Low | Improbable | 1 | Yes |

RACI

PLACEHOLDER A RACI is an important documentation process to let people know what ACTIONS can happen, and who needs to be Responsible, Accountable, Consulted and Informed for each ACTION. Delete this line.

| Task / Action | Executive | Cause Leader Cause Team | Named Maintainer | Trainers | Cause | Membership | Implementer |

|---|---|---|---|---|---|---|---|

| Modification and Repairs | - | AC | C | I | I | I | R |

| Induction changes | C | RACI | RC | I | I | I | R |

Decision Register

PLACEHOLDER: A decision register is for general documentation when some decision is made regarding the tool. To change its location, mode of operation, to buy an accessory, to replace something, to change how it operates etc. Delete this line.

| Ref / ID | Decision Details | Impact | Proposed Date | Proposed By | Status | Approved By | Date | Resulting Actions and Comments |

|---|---|---|---|---|---|---|---|---|

| 0000 | Example decision | Provides an example | 08/08/20 | JH | Approved | JH | 08/08/20 | A line was put in the register |