PLACEHOLDER

This is the template for a machine. Please copy and paste this to make new machine pages.

Please pay close attention, this template provides multiple options and placeholder text. You will need to select the correct option and replace all placeholder text.

Please do not remove entire sections, they're there for a reason.

Delete this box when you are done.

Casting Furnace

|

| Owned by | Dave Seff |

| Maintained by | Dave Seff |

| Trainers | Alex |

Current Status

Working

Machine is working as expected.

Usage

This machine requires induction to use.

How to get inducted

- Read the “Casting Area Induction” below

- Post in the Forge channel on Discord to arrange for a time to be inducted

Guidelines

PLACEHOLDER: This is where you can document the usage practices for the machine generally. If this section gets very long, then it should be part of a canvas course for induction. Don't document maintenance procedures here, please do that below in the maintenance section. Delete this line.

Recommended PPE

| Required |  | We recommend hearing protection. |

| Required |  | Please wear goggles or a face shield |

| Recommended |  | The use of a respirator is required when melting certain metals |

| Required |  | Enclosed shoes are required, no open sandals, thongs etc. Safety caps are recommended. |

| Required | Long pants required. | |

| Required | No Synthetic materials or clothing. | |

| Required |  | Gloves are required |

Machine Specifications

PLACEHOLDER: Please fill out this table with all relevant machine specifications. The manufacturers website usually gives a good list. Delete this line.

| Name | Value |

|---|---|

| Attribute A | 305mm |

| Attribute B | 1600 mm x 270 mm |

| Attribute C | 3.0 hp |

Documents

PLACEHOLDER: Please copy the two WRAP blocks below for each file you upload relevant to this machine. This should be the manual at a minimum. Delete this line.

Manufacturer

PLACEHOLDER: Document the manufacturer, things like contact person names, emails, phone numbers, product urls etc. Document the reseller we bought from, and any other sources for similar things. Delete this line.

Manufacturer

- E sales@example.com

- P 00 0000 0000

Reseller

- Mr. Re seller

- Reseller Agencies

- E sales@reseller.com

- M 0000 000 000

Known Identical Models

- Links to other machines that are a rebrand or similar

Known Issues

| Date | Description | Workaround | Proposed Remediation |

|---|---|---|---|

| 01/01/2020 | PLACEHOLDER Describe the problem | PLACEHOLDER Describe the workaround currently in place | Placeholder Describe a proposed fix or solution |

Modifications / Repair History

| Date | Modified By | Description | Remediation | Cost |

|---|---|---|---|---|

| 01/01/2020 | PLACEHOLDER NAME | PLACEHOLDER Describe what happened | PLACEHOLDER Describe how it was fixed or modified | PLACEHOLDER document the cost of the change |

Accessories

| Image | Category | Accessory Name & Notes | Location | Buy from |

|---|---|---|---|---|

| PLACEHOLDER Image, 100 width | PLACEHOLDER Category of accessory | PLACEHOLDER Accessory Name PLACEHOLDER Description and usage notes for accessory | PLACEHOLDER Describe location of accessory | PLACEHOLDER Link to where it was bought from |

Consumables & Running Costs

| Image | Category | Accessory Name & Notes | Location | Buy from |

|---|---|---|---|---|

| PLACEHOLDER Image, 100 width | PLACEHOLDER Category of consumable | PLACEHOLDER Consumable Name PLACEHOLDER Consumable description and usage | PLACEHOLDER Description of where the consumable is stored | PLACEHOLDER Link to where it can be bought |

Maintenance

| Interval | Task |

|---|---|

| PLACEHOLDER Pick one: Daily/Weekly/Monthly/Quarterly/Biannual/Annual | PLACEHOLDER Description of maintenance task and any relevant parameters |

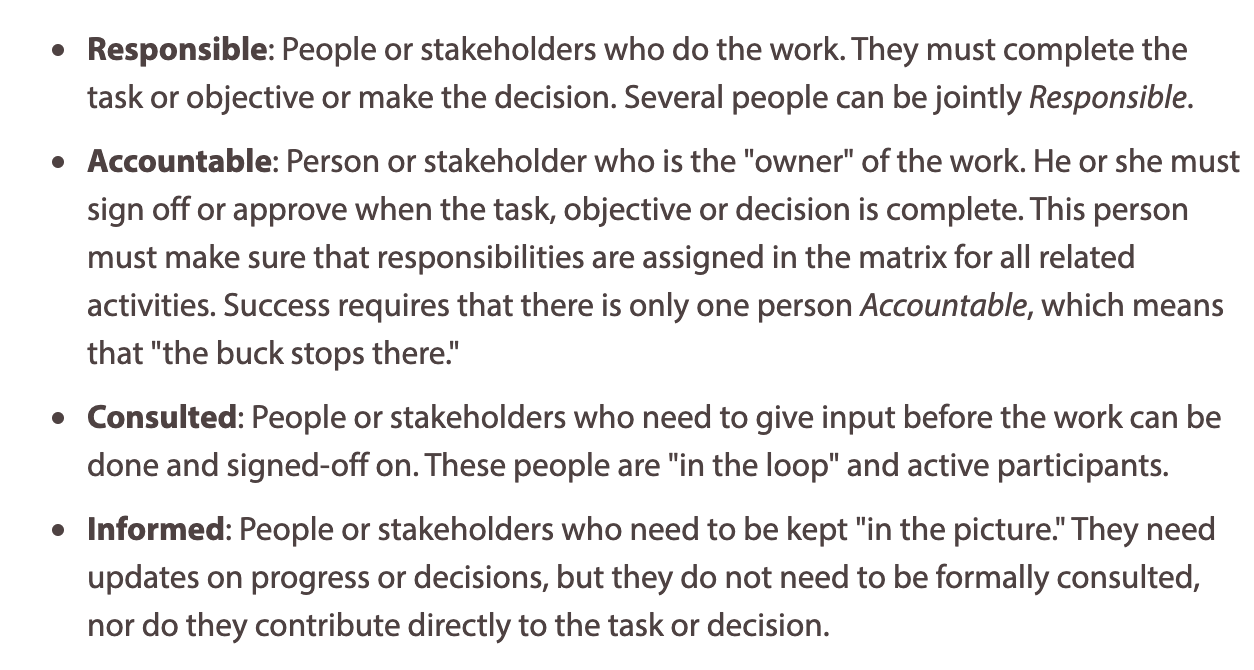

RACI

| Task / Action | Executive | Team Leader | Named Maintainer | Trainers | Team | Membership | Implementer |

|---|---|---|---|---|---|---|---|

| Modification and Repairs | - | AC | C | I | I | I | R |

| Induction changes | CI | CI | CI | ACI | I | I | R |

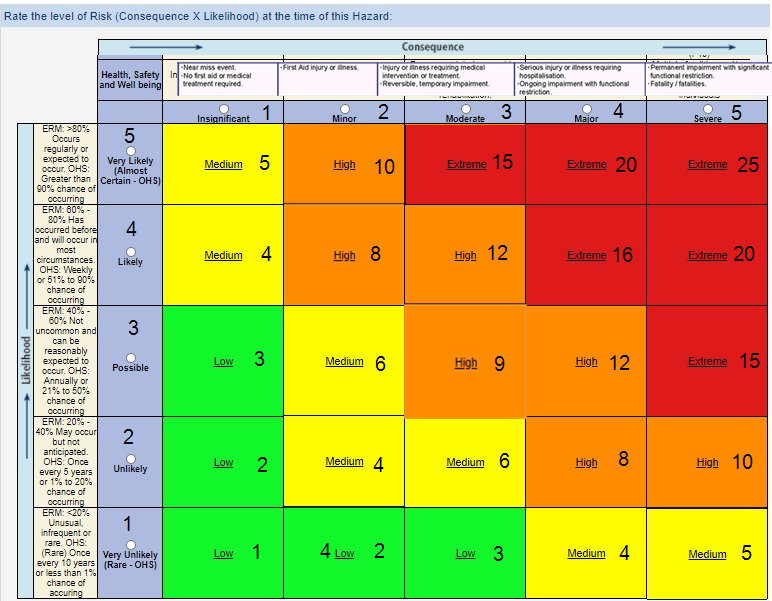

Risk Matrix and Mitigation

| Ref / ID | Pre-Mitigation | Mitigations / Warnings / Remedies | Post Mitigation | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Risk | Risk Severity | Risk Likelyhood | Risk Level | Risk Severity | Risk Likelyhood | Risk Level | Acceptable to Proceed | ||

| 01 | Uncontained fire | Major | Likely | 16 - Extreme | Induction to train users in correct usage, no flammables around forge | Unlikely | Insignificant | 2 - Low | Yes |

| 02 | Silicosis | Major | Possible | 12 - High | Forge is regularly maintained | Unlikely | Insignificant | 2 - Low | Yes |

| 03 | Fumes and vapours | Severe | Possible | 15 - Extreme | Induction to train users in correct usage | Unlikely | Insignificant | 2 - Low | Yes |

| 04 | Flashbacks | Moderate | Possible | 9 - High | Induction to train users in correct usage | Unlikely | Insignificant | 2 - Low | Yes |

| 05 | Minor Explosion by improper lighting | Likely | Moderate | 12 - High | Induction to train users on how to light the forge | Unlikely | Insignificant | 2 - Low | Yes |

| 06 | Explosion from leakage from gas bottle | Severe | Unlikely | 10 - High | Induction to train users on how to detect and fix gas leak | Unlikely | Insignificant | 2 - Low | Yes |

| 07 | Minor Burn | Insignificant | Likely | 4 - Medium | Wear PPE, use appropriate tooling, water on hand, first aid kit | Unlikely | Insignificant | 2 - Low | Yes |

| 08 | Moderate Burn | Minor | Possible | 6 - Medium | Wear PPE, water on hand, use appropriate tooling, first aid kit | Unlikely | Insignificant | 2 - Low | Yes |

| 09 | Major Burn | Major | Unlikely | 8 - High | Wear PPE, use appropriate tooling, water on hand, first aid kit | Unlikely | Minor | 4 - Low | Yes |

| 10 | Flying Sparks | Insignificant | Likely | 4 - Medium | Wear PPE, water on hand, first aid kit | Unlikely | Insignificant | 2 - Low | Yes |

| 11 | Industrial Noise | Minor | Very Likely | High - 10 | Wear PPE | Unlikely | Insignificant | 2 - Low | Yes |

| 12 | IR radiation burns to eyes and skin | Minor | Likely | 10 | Wear PPE | Unlikely | Insignificant | 2 - Low | Yes |

| 13 | Steam Explosion | Severe | Unlikely | 10 - High | Induction to train users on the correct moisture content of green sand | Unlikely | Insignificant | 2 - Low | Yes |

| 14 | Molten Metal Spill | Severe | Unlikely | 10 - High | Induction to train users on to pour correctly | Unlikely | Insignificant | 2 - Low | Yes |

Decision Register

PLACEHOLDER: A decision register is for general documentation when some decision is made regarding the tool. To change its location, mode of operation, to buy an accessory, to replace something, to change how it operates etc. Delete this line.

| Ref / ID | Decision Details | Impact | Proposed Date | Proposed By | Status | Approved By | Date | Resulting Actions and Comments |

|---|---|---|---|---|---|---|---|---|

| 0000 | Example decision | Provides an example | 08/08/20 | JH | Approved | JH | 08/08/20 | A line was put in the register |

Casting Area Induction

Work in progress