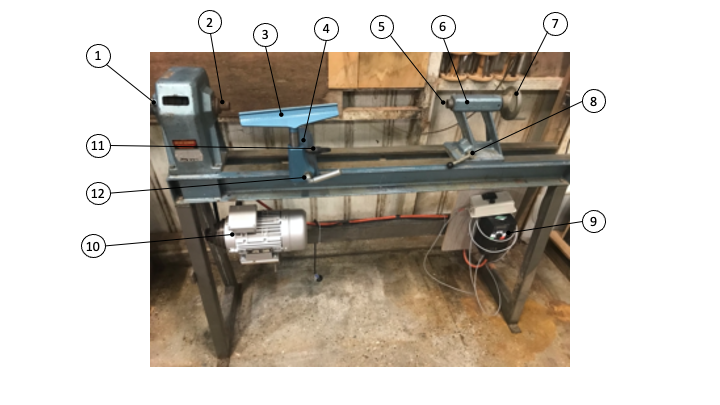

Vicmark Lathe VL200

| Aliases | Vicmark VL200 |

| The Better Lathe | |

| Official Maintainer | To be determined |

Current Status

Out of Order

Machine is currently in the process of being restored.

Ale, Josh and Murray are currently working on this.

See Trello Card

Usage

This machine requires induction to use.

Guidelines

Recommended PPE

PLACEHOLDER: There is a large collection of PPE Icons in the “resources” folder. Please update these two columns with appropriate PPE recommendations. Columns of the tables are “Recommended/Required/Warning/Maintenance”, PPE Icon and Description. Delete this line.

| Recommended |  | We recommend hearing protection. |

| Recommended |  | Please wear goggles or a face shield |

| Recommended |  | We recommend the use of a respirator |

| Maintenance |  | Disconnect power to the lathe before performing maintenance, including changing belt speed |

| Maintenance |  | Ensure lathe is stopped before adjusting accessories such as tool rests. |

Machine Specifications

| 1 | Outboard Spindle / Handwheel |

| 2 | Headstock Spindle |

| 3 | Toolrest |

| 4 | Camlock / Banjo |

| 5 | Quill |

| 6 | Tailstock |

| 7 | Tailstock handwheel |

| 8 | Tailstock locking lever |

| 9 | Speed Controller / Inverter |

| 10 | Motor |

| 11 | Toolrest locking lever |

| 12 | Camlock / Banjo Locking lever |

Speed controller/inverter

| Name | Value |

|---|---|

| Model | S1100V Control Inverter |

| Voltage Level | 4T (3phase 415 V) |

| Max Motor Power | — |

| Torque | — |

Motor

| Name | Value |

|---|---|

| Model | MSE3-90L-2 |

| Serial | B20041800154 |

| Power | 3.0 hp |

| Volt | 240/415 |

| Power | 2.2 KW |

| Amps | 7.29/4.19 |

| Hz | 50.0 |

| RPM | 2915 |

| Connections | delta Y |

| Manuf Ph | 02 9607 4100 |

Lathe Bed

| Name | Value |

|---|---|

| Attribute A | 305mm |

| Attribute B | 1600 mm x 270 mm |

| Attribute C | 3.0 hp |

Documents

Manufacturer

Manufacturer

Vicmarc

Reseller

- Details TBA

Known Issues

| Date | Description | Workaround | Proposed Remediation |

|---|---|---|---|

| 01/01/2020 | PLACEHOLDER Describe the problem | PLACEHOLDER Describe the workaround currently in place | Placeholder Describe a proposed fix or solution |

Modifications / Repair History

| Date | Modified By | Description | Remediation | Cost |

|---|---|---|---|---|

| –/10/2020 | External Speed Controller | Start/Stop & speed control dial added | Start/Stop button and a speed control dial wired to controller. Controller registers adjusted to use terminal inputs | <~$50 |

| 04/01/2021 | Murray, Duncan | Head stock bearings heating up & unstable at high speed | Remove and repack with bearing grease | $0ish |

Accessories

| Image | Category | Accessory Name & Notes | Location | Buy from |

|---|---|---|---|---|

| Workpiece Holding | 4 Jaw Self-Centring Chuck VM120 V00285-1 For general work holding. Vicmarc 4-Jaw Chuck Manual | TBA | TBA |

| Workpiece Holding | Drive Dog 25mm Heavy Duty V00341 MT2 drive dog for inserting in the headstock spindle. | TBA | TBA |

| Workpiece Holding | Live Centre MT2 Cone Heavy Duty V00269 live centre for inserting in the tailstock. | TBA | TBA |

| Workpiece Holding | Face Plate 125mm faceplate V00412-1; For holding large pieces for roughing | TBA | TBA |

| Workpiece Holding | Screw Point For mounting small cross grain pieces | TBA | TBA |

| Accessory Tooling | Chuck Tools 10mm and 4mm T-Handled Allen Key Wrenches | TBA | TBA |

Consumables & Running Costs

| Image | Category | Accessory Name & Notes | Location | Buy from |

|---|---|---|---|---|

| PLACEHOLDER Image, 100 width | PLACEHOLDER Category of consumable | PLACEHOLDER Consumable Name PLACEHOLDER Consumable description and usage | PLACEHOLDER Description of where the consumable is stored | PLACEHOLDER Link to where it can be bought |

Maintenance

| Interval | Task | |

|---|---|---|

| PLACEHOLDER Pick one: Daily/Weekly/Monthly/Quarterly/Biannual/Annual | PLACEHOLDER Description of maintenance task and any relevant parameters | Last Check |

| Quarterly | check inverter heatsink is free of dust. Exhaust fan at top of unit must be operational and no dust on heatsink | 6/10/2020 |

| Quarterly | Belt Condition | — |

| Annual | pulley condition | — |

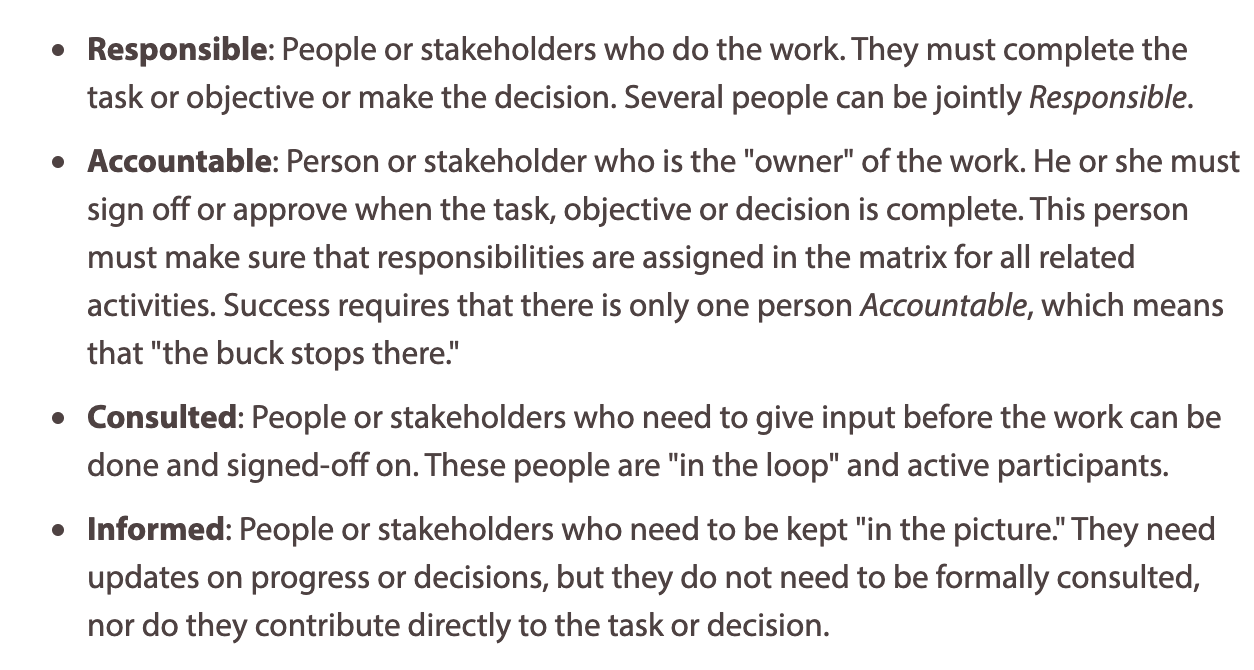

RACI

PLACEHOLDER A RACI is an important documentation process to let people know what ACTIONS can happen, and who needs to be Responsible, Accountable, Consulted and Informed for each ACTION. Delete this line.

| Task / Action | Executive | Cause Leader Cause Team | Named Maintainer | Trainers | Cause | Membership | Implementer |

|---|---|---|---|---|---|---|---|

| Modification and Repairs | - | AC | C | I | I | I | R |

| Induction changes | C | RACI | RC | I | I | I | R |

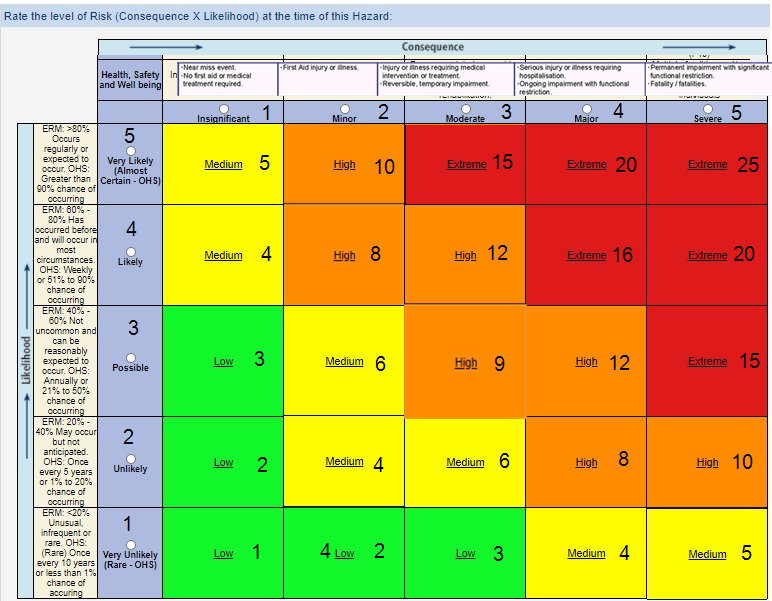

Risk Matrix and Mitigation

PLACEHOLDER: Risk assessment is important to ensure we are making tools available to members in a responsible fashion. Please make every effort to do a reasonable risk assessment. If there is a safety incident with the tool, please redo a risk assessment and add it to the table.

| Ref / ID | Pre-Mitigation | Mitigations / Warnings / Remedies | Post Mitigation | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Risk | Risk Severity | Risk Likelyhood | Risk Level | Risk Severity | Risk Likelyhood | Risk Level | Acceptable to Proceed | ||

| 0001 | PLACEHOLDER DEATH | Intolerable | Probable | 11 | PLACEHOLDER Induction to train users in correct usage | Low | Improbable | 1 | |

Decision Register

PLACEHOLDER: A decision register is for general documentation when some decision is made regarding the tool. To change its location, mode of operation, to buy an accessory, to replace something, to change how it operates etc. Delete this line.

| Ref / ID | Decision Details | Impact | Proposed Date | Proposed By | Status | Approved By | Date | Resulting Actions and Comments |

|---|---|---|---|---|---|---|---|---|

| 0000 | Example decision | Provides an example | 08/08/20 | JH | Approved | JH | 08/08/20 | A line was put in the register |