Gas Forge

| Aliases | “the forge” |

| Official Maintainer | Alex Wixted |

| Owned by | Forge Team |

| Trainers | Alex / Jess |

Current Status

Working

Machine is working as expected.

Usage

This machine requires an induction to use.

How to get inducted

- Read the “Gas Forge Standard Operating Procedure” below

- Post in the Forge channel on Discord to arrange for a time to be inducted

General

Put material into forge to heat up.

Only put steel into the forge. No galvanised / zinc coated / stainless / copper / etc. If unsure, ask.

Put hot materials / tools under the forge to cool down before putting them away.

Forge consumes $5 of LPG per hour while running. Please remember to donate to the forge.

Addons

| Adjustable roller for long material |

Potential improvements

A smaller, more efficient forge.

Machine Specifications

| Name | Value |

|---|---|

| Maximum size of workpiece |

Recommended PPE

| Recommended |  | We recommend hearing protection. |

| Required |  | Please wear goggles or a face shield |

| Required |  | Enclosed shoes are required, no open sandals, thongs etc. Safety caps are recommended. |

| Required | Long pants required. | |

| Required | No Synthetic materials or clothing. |

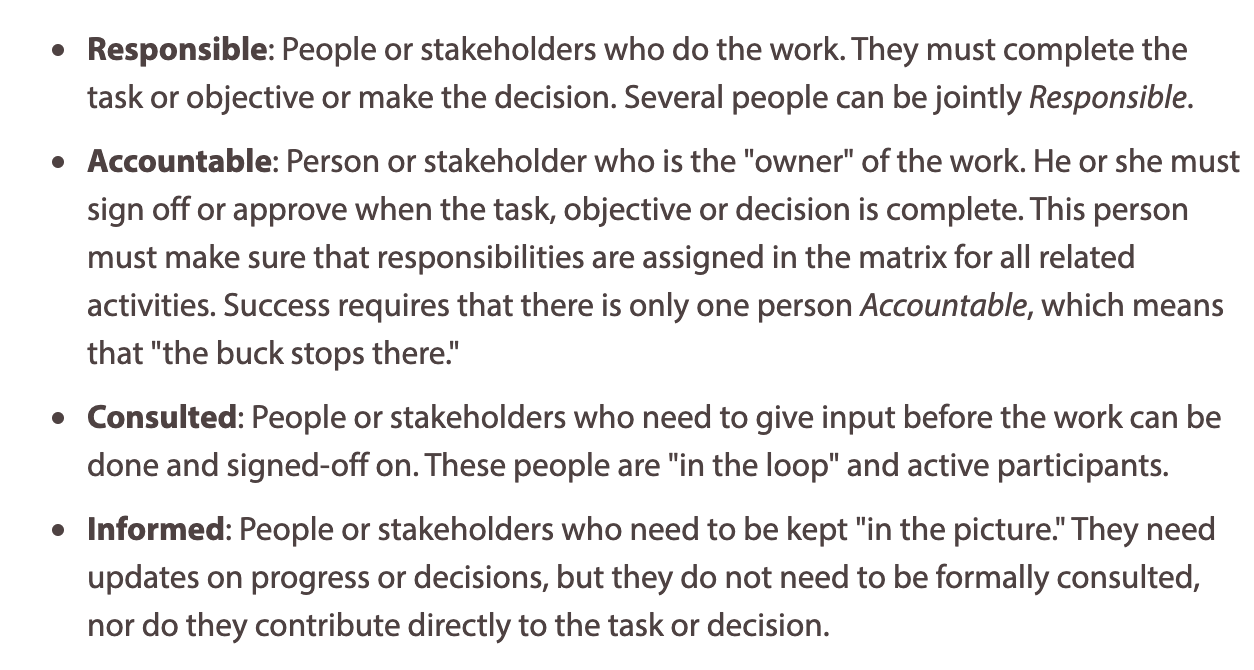

RACI

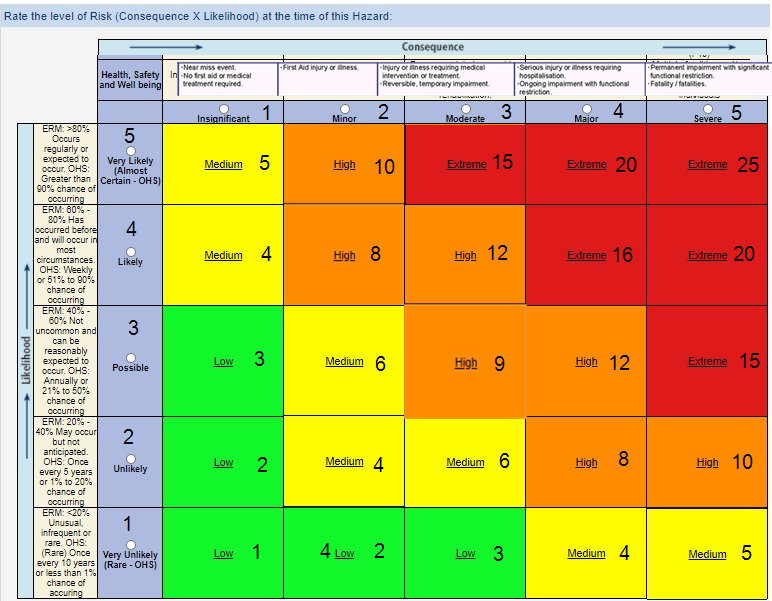

Risk Matrix and Mitigation

| Ref / ID | Pre-Mitigation | Mitigations / Warnings / Remedies | Post Mitigation | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Risk | Risk Severity | Risk Likelyhood | Risk Level | Risk Severity | Risk Likelyhood | Risk Level | Acceptable to Proceed | ||

| 01 | Uncontained fire | Major | Likely | 16 - Extreme | Induction to train users in correct usage, no flammables around forge | Unlikely | Insignificant | 2 - Low | Yes |

| 02 | Silicosis | Major | Possible | 12 - High | Forge is regularly maintained | Unlikely | Insignificant | 2 - Low | Yes |

| 03 | Fumes and vapours | Severe | Possible | 15 - Extreme | Induction to train users in correct usage | Unlikely | Insignificant | 2 - Low | Yes |

| 04 | Flashbacks | Moderate | Possible | 9 - High | Induction to train users in correct usage | Unlikely | Insignificant | 2 - Low | Yes |

| 05 | Minor Explosion by improper lighting | Likely | Moderate | 12 - High | Induction to train users on how to light the forge | Unlikely | Insignificant | 2 - Low | Yes |

| 06 | Explosion from leakage from gas bottle | Severe | Unlikely | 10 - High | Induction to train users on how to detect and fix gas leak | Unlikely | Insignificant | 2 - Low | Yes |

| 07 | Minor Burn | Insignificant | Likely | 4 - Medium | Wear PPE, use appropriate tooling, water on hand, first aid kit | Unlikely | Insignificant | 2 - Low | Yes |

| 08 | Moderate Burn | Minor | Possible | 6 - Medium | Wear PPE, water on hand, use appropriate tooling, first aid kit | Unlikely | Insignificant | 2 - Low | Yes |

| 09 | Major Burn | Major | Unlikely | 8 - High | Wear PPE, use appropriate tooling, water on hand, first aid kit | Unlikely | Minor | 4 - Low | Yes |

| 10 | Flying Sparks | Insignificant | Likely | 4 - Medium | Wear PPE, water on hand, first aid kit | Unlikely | Insignificant | 2 - Low | Yes |

| 11 | Industrial Noise | Minor | Very Likely | High - 10 | Wear PPE | Unlikely | Insignificant | 2 - Low | Yes |

| 12 | IR radiation burns to eyes and skin | Minor | Likely | 10 | Wear PPE | Unlikely | Insignificant | 2 - Low | Yes |

Gas Forge Standard Operating Procedure

The Gas Forge induction must be completed in person prior to use. Post in the Forge Discord channel to arrange a time.

Required PPE:

- Safety Glasses

- Leather shoes

- Natural fibre clothing (Cotton, wool, hemp, denim, drill etc are all excellent choices.)

- Long Trousers

Recommended PPE:

- Hearing protection

- Long sleeve shirt (natural fibre)

- Steel cap shoes

- Hat/cap (natural fibre)

- Apron

Use as necessary PPE:

- Leather gloves

- Brazing goggles (shade #2 or #3)

SOP: Lighting the gas forge

- Ensure ball valve (yellow handle) is closed.

- Ensure air/venturi adjustment port is closed.

- Connect gas bottle securely

- Open gas bottle valve and check for leaks by listening, smelling and using gas leak. If there are leaks check and tighten connections.

- Adjust the gas flow valve to a medium flow.

- Use some firelight or a long nose BBQ lighter to provide a pilot light in the forge.

- Open Ball valve fully.

- Once lit, open and adjust the air/venturi port until the flame changes to a strong jet within the forge.

- Adjust gas flow valve and air/venturi port until desired burner strength is achieved.

SOP: Extinguishing the gas forge:

- If you are not finished forging for the day, you can use the ball valve for ease of use. Close the air/venturi port to prevent a heat chimney. While the forge is still red hot it will relight instantly.

- When you are finished forging for the day, close the valve on the gas bottle, and let the forge run until the line is clear of gas. Close the ball valve and air/venturi port, and disconnect the gas bottle. The yellow safety cap must be put back into the gas bottle and the gas bottle must go back into the gas storage cage even if the gas bottle is empty.

Forge Best Practices:

- The gas forge is for steel only. No galvanised / zinc coated / stainless / copper / etc, If unsure, ask. Absolutely no hazardous materials such as lead should be placed into the forge – This will earn you an instant 3 month ban as we will need to replace the forge for safety.

- Certain metals such as copper/brass/titanium may be used in the gas forge after a discussion around the required precautions. (eg: melted copper in the forge will permanently contaminate the forge and prevent all future forge welding from being successful. Precautions to avoid melting copper into the forge should be taken)

- Don’t use borax in the gas forge, unless discussed prior & and appropriate precautions are taken.

- Do use the forge hook for pulling items close to the front before picking them up.

- Don’t leave the forge unattended while in use.

- Don't put hot tools back into the tool rack. Put them under the forge until they are cool to hold.

General Forge Area Safety

- Bring a water bottle – forging is hot work and you need to keep your hydration levels up.

- Always remove cut off hardy’s from the anvil hardy hole when not in use.

- Find the right height anvil for you – you will generate more power and injure yourself less.

- Check tong fit on your cold steel first.

- Assume everything is hot – use the back of your hand to check for radiant heat first.

- tools/blacksmithing/gasbottlefurnace

- Last modified: 3 years ago

- by

zacmarcus

zacmarcus