This is an old revision of the document!

| Aliases | Up Mini |

| Other References | |

| Official Maintainer | Brendan Halliday |

Not Working

Machine is not working as expected, it has been taken off site to be maintained due to a nozzle clog.

This machine is generally available to use.

| Required |  | Enclosed shoes are required, no open sandals, thongs etc |

| Required |  | These absolutely must be used while removing prints from the printer bed. |

| Name | Value |

| Printing Area | 100x100x100mm |

Manufacturer

Reseller

Known Identical Models

| Date | Description | Workaround | Proposed Remediation |

| Jun 2019 | UP! Studio Software generates print jobs that fail after several layers. | Use the UP! 2.18 Software instead. | Uninstall UP! Studio from PC. |

| Date | Modified By | Description | Remediation | Cost |

| Jun 2018 | Brendan Halliday | Nozzle replaced. | Old nozzle was clogged with debris that could not be shifted with soaking in ABS. It was binned. | $25 AUD |

| Image | Category | Accessory Name & Notes | Location | Buy from |

| Core Tool | Bed Scraper

Bed scraper for removing prints from perfboard. | Side of Machine | N/A |

| Core Tool | Bench Hook

Bench Hook for supporting the removed Up Mini perfboard while print is being removed. | Side of Machine | N/A |

| Maintenance tool | Nozzle Wrench

Wrench for undoing nozzle. Only to be used by tool maintainer(s). Always make sure nozzle is at extrusion temperature before using. | Side of Machine | N/A |

Maintenance

| Interval | Task |

| Monthly | Filament extrusion - to ensure nozzle is clean. |

| Monthly | Bed clean - Scrape the beds clean |

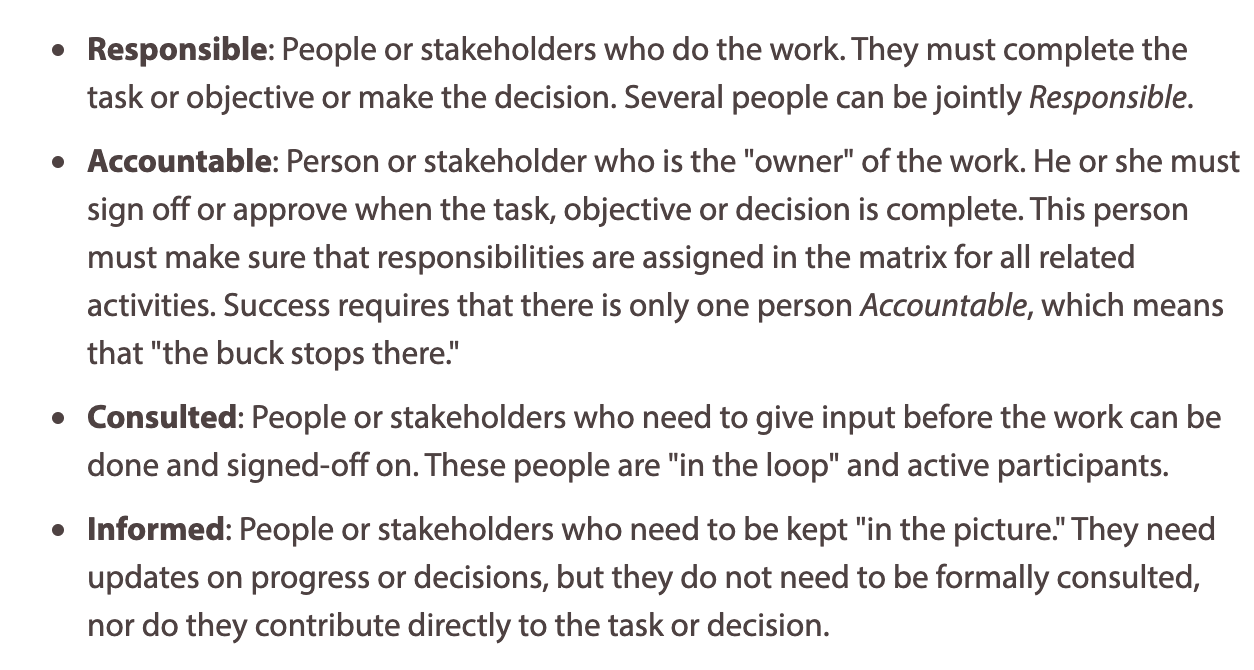

| Task / Action | Executive | Cause Leader

Cause Team | Named Maintainer | Trainers | Cause | Membership | Implementer |

| Modification and Repairs | - | AC | RAC | I | I | I | R |

| Induction changes | C | RACI | RC | I | I | I | R |

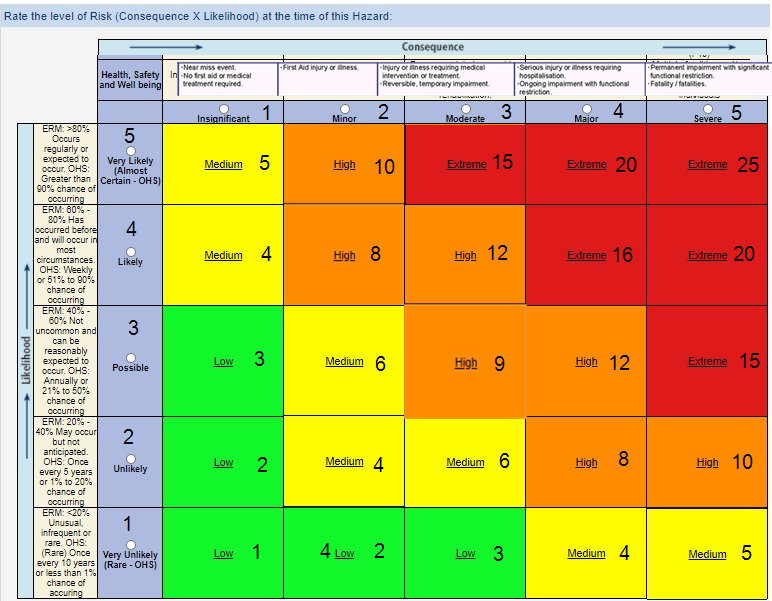

Risk Matrix and Mitigation

| Ref / ID | Pre-Mitigation | Mitigations / Warnings / Remedies | Post Mitigation |

| Risk | Risk Severity | Risk Likelyhood | Risk Level | Risk Severity | Risk Likelyhood | Risk Level | Acceptable to Proceed |

| 0001 | Fire | Tolerable | Improbable | 4 | Induction to train users in correct usage | Low | Improbable | 1 | |

| Ref / ID | Decision Details | Impact | Proposed Date | Proposed By | Status | Approved By | Date | Resulting Actions and Comments |

hsbnewiki

hsbnewiki