This is an old revision of the document!

Mill, Turret - Pacific FTV-2S

| Aliases | Manual Mill |

| Other References | |

| Official Maintainer |

Current Status

Working

Machine is working as expected.

Usage

This machine requires induction to use.

Request an induction in the metalshop channel on the HSBNE discord server, or create a post in the metalworking section of the forums. Inductions typically run on Tuesday nights, but alternative times can be arranged upon request.

Personal Protective Equipment

| Required |  | Always wear AS/NZS 1337.1 compliant safety glasses while operating this machine. |

| Required |  | Enclosed shoes are required, no open sandals, thongs etc |

| Required |  | Restrain hair while operating machine |

| Recommended |  | We recommend hearing protection. |

| Warning |  | Entanglement hazard present while wearing gloves. |

| Maintenance |  | Disconnect power to the machine before performing maintenance, including wheel changes |

Machine Specifications

PLACEHOLDER: Please fill out this table with all relevant machine specifications. The manufacturers website usually gives a good list. Delete this line.

| Name | Value |

|---|---|

| Motor Power | 3 Phase, 415V |

| Spindle Style | ISO40, M16 Drawbar |

| Spindle Speed | 50-4000RPM, Continuous |

Documents

PLACEHOLDER: Please copy the two WRAP blocks below for each file you upload relevant to this machine. This should be the manual at a minimum. Delete this line.

Manufacturer

PLACEHOLDER: Document the manufacturer, things like contact person names, emails, phone numbers, product urls etc. Document the reseller we bought from, and any other sources for similar things. Delete this line.

Manufacturer

- E sales@example.com

- P 00 0000 0000

Reseller

- Mr. Re seller

- Reseller Agencies

- E sales@reseller.com

- M 0000 000 000

Known Identical Models

- Links to other machines that are a rebrand or similar

Known Issues

| Date | Description | Workaround | Proposed Remediation |

|---|---|---|---|

| 01/01/2020 | PLACEHOLDER Describe the problem | PLACEHOLDER Describe the workaround currently in place | Placeholder Describe a proposed fix or solution |

Modifications / Repair History

| Date | Modified By | Description | Remediation | Cost |

|---|---|---|---|---|

| 01/01/2020 | PLACEHOLDER NAME | PLACEHOLDER Describe what happened | PLACEHOLDER Describe how it was fixed or modified | PLACEHOLDER document the cost of the change |

Accessories

| Image | Category | Accessory Name & Notes | Location | Buy from |

|---|---|---|---|---|

| PLACEHOLDER Image, 100 width | PLACEHOLDER Category of accessory | PLACEHOLDER Accessory Name PLACEHOLDER Description and usage notes for accessory | PLACEHOLDER Describe location of accessory | PLACEHOLDER Link to where it was bought from |

Consumables & Running Costs

| Image | Category | Accessory Name & Notes | Location | Buy from |

|---|---|---|---|---|

| PLACEHOLDER Image, 100 width | PLACEHOLDER Category of consumable | PLACEHOLDER Consumable Name PLACEHOLDER Consumable description and usage | PLACEHOLDER Description of where the consumable is stored | PLACEHOLDER Link to where it can be bought |

Maintenance

| Interval | Task |

|---|---|

| Daily | Apply 'one-shot' oil Check oil level in machine head. Run gearbox through full speed range |

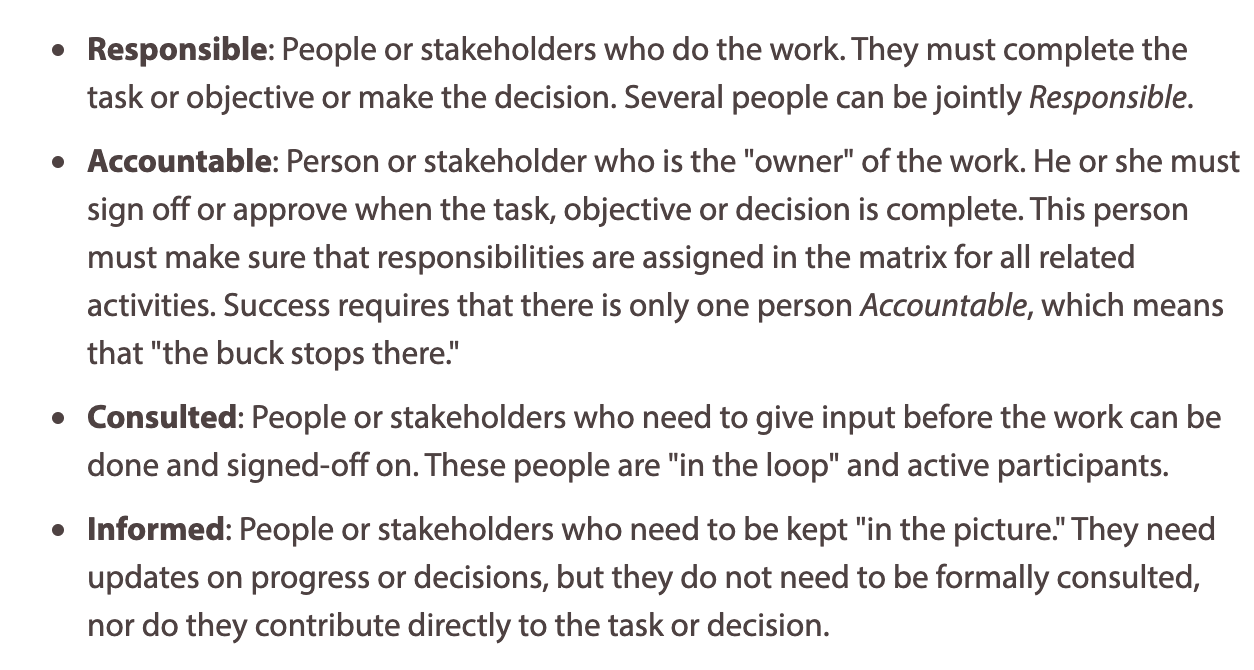

RACI

| Task / Action | Executive | Cause Leader Cause Team | Named Maintainer | Trainers | Cause | Membership | Implementer |

|---|---|---|---|---|---|---|---|

| Modification and Repairs | - | AC | C | I | I | I | R |

| Induction changes | C | RACI | RC | I | I | I | R |

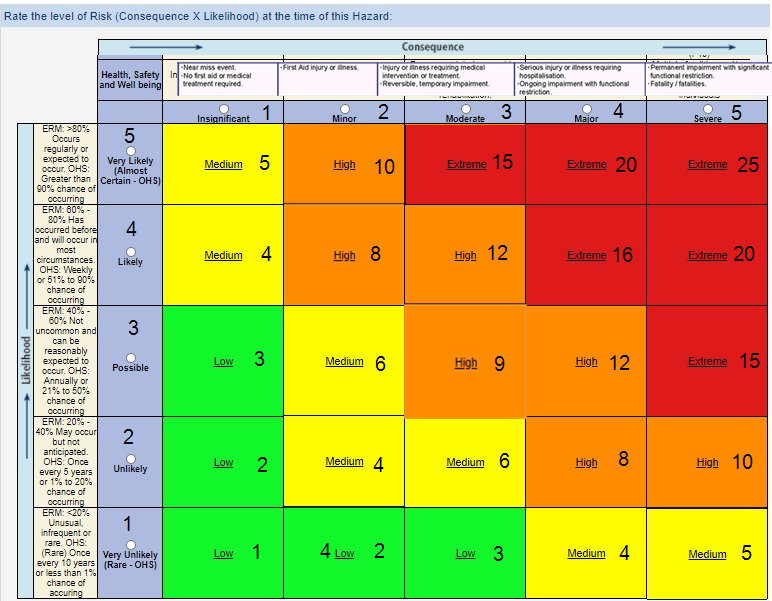

Risk Matrix and Mitigation

PLACEHOLDER: Risk assessment is important to ensure we are making tools available to members in a responsible fashion. Please make every effort to do a reasonable risk assessment. If there is a safety incident with the tool, please redo a risk assessment and add it to the table.

| Ref / ID | Pre-Mitigation | Mitigations / Warnings / Remedies | Post Mitigation | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Risk | Risk Severity | Risk Likelyhood | Risk Level | Risk Severity | Risk Likelyhood | Risk Level | Acceptable to Proceed | ||

| 0001 | PROJECTILE | Intolerable | Probable | 8 | Induction to train users in correct usage. Require use of appropriate PPE. | Low | Possible | 2 | |

| 0002 | ENTANGLEMENT | Intolerable | Probable | 8 | Induction to train users in correct usage. Discourage Glove Use | Low | Possible | 2 | |

Decision Register

PLACEHOLDER: A decision register is for general documentation when some decision is made regarding the tool. To change its location, mode of operation, to buy an accessory, to replace something, to change how it operates etc. Delete this line.

| Ref / ID | Decision Details | Impact | Proposed Date | Proposed By | Status | Approved By | Date | Resulting Actions and Comments |

|---|---|---|---|---|---|---|---|---|

| 0000 | Example decision | Provides an example | 08/08/20 | JH | Approved | JH | 08/08/20 | A line was put in the register |

- tools/metalshop/3axismill.1609973139

- Last modified: 3 years ago

- by

ryan6338

ryan6338