Grinder, Bench, 200mm - Linishall BG6

| Aliases | “Bench Grinder” |

| Other References | |

| Official Maintainer | Ben Jackson |

Current Status

Historical: This machine is in storage or HSBNE no longer has this machine.

Usage

This machine requires induction to use.

Book an induction on Eventbrite.

https://www.eventbrite.com/cc/metalshop-inductions-804979

Personal Protective Equipment

| Required |  | Always wear AS/NZS 1337.1 compliant safety glasses while operating this machine. |

| Required |  | Enclosed shoes are required, no open sandals, thongs etc |

| Required |  | Restrain hair while operating machine |

| Prohibited |  | Loose clothing and jewellery not to be worn while operating this machine. |

| Recommended |  | We recommend hearing protection. |

| Recommended |  | We recommend the use of a respirator |

| Warning |  | Entanglement hazard present while wearing gloves. |

| Maintenance |  | Disconnect power to the machine before performing maintenance, including wheel changes |

Machine Specifications

| Name | Value |

|---|---|

| Motor Power | Single Phase, 240V, 450W |

| Wheel Size | 150mm x 20mm |

| Speed | 2880 RPM |

| Spindle Shaft Thread | M12 x 1.75 (left side Reverse thread) |

Documents

Manufacturer

Manufacturer

- Garrick Herbert Pty Ltd

- E sales@garrickherbert.com.au

- P 02 9545 6633

Reseller

- Hare & Forbes Machineryhouse

- P 07 3715 2200

Known Identical Models

Known Issues

| Date | Description | Workaround | Proposed Remediation |

|---|

Modifications / Repair History

| Date | Modified By | Description | Remediation | Cost |

|---|

Accessories

| Image | Category | Accessory Name & Notes | Location | Buy from |

|---|

Consumables & Running Costs

| Image | Category | Accessory Name & Notes | Location | Buy from |

|---|---|---|---|---|

| Grinding Wheel | 150mm x 20mm (not 25mm) Grinding Wheel | Total Tools |

Maintenance

| Interval | Task |

|---|---|

| Monthly | Check and redress wheels |

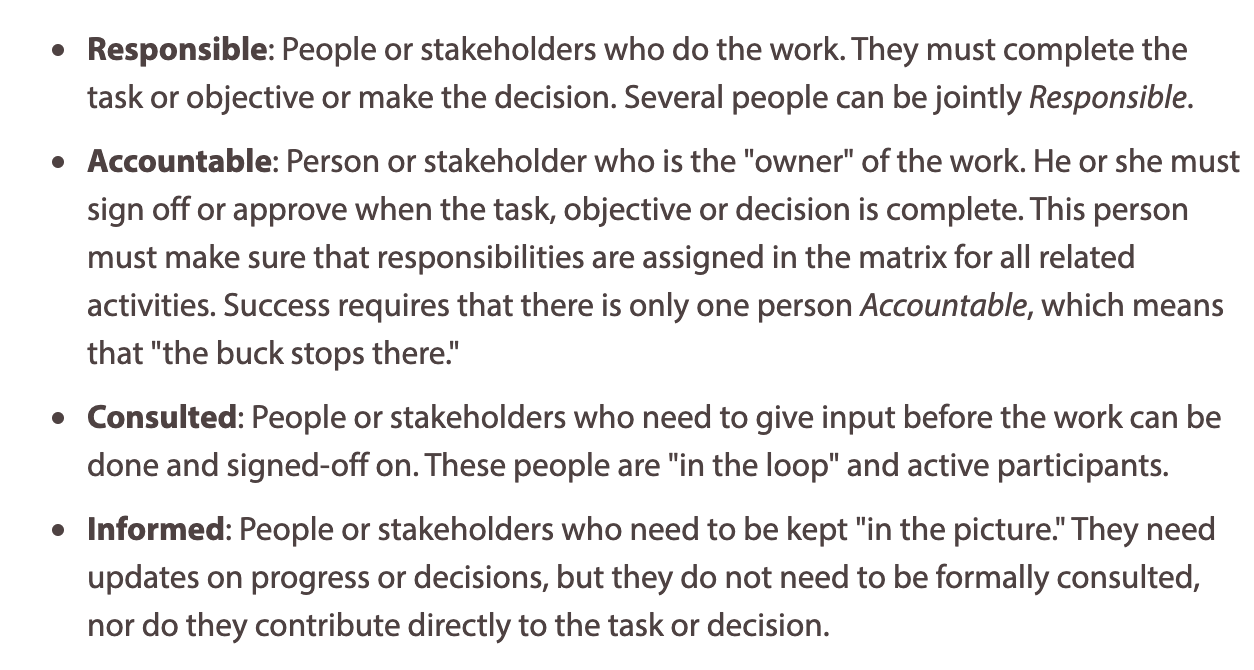

RACI

| Task / Action | Executive | Cause Leader Cause Team | Named Maintainer | Trainers | Cause | Membership | Implementer |

|---|---|---|---|---|---|---|---|

| Modification and Repairs | - | AC | C | I | I | I | R |

| Induction changes | C | RACI | RC | I | I | I | R |

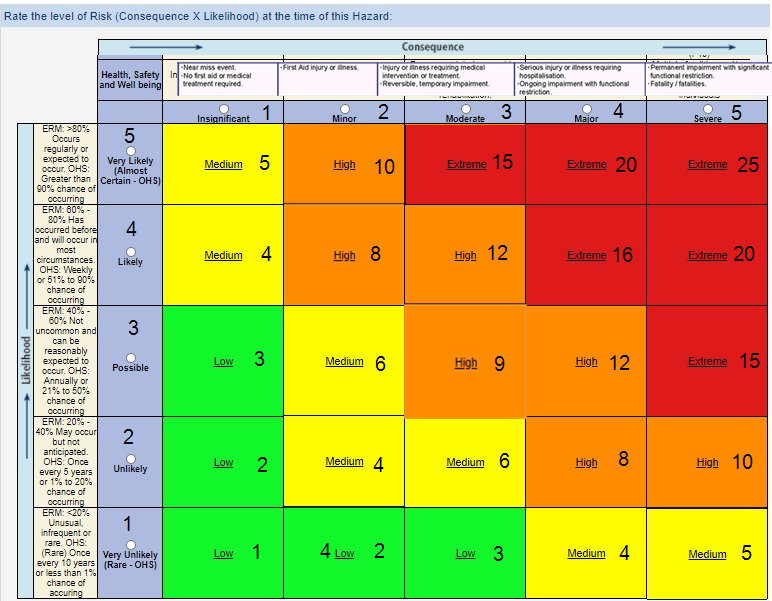

Risk Matrix and Mitigation

PLACEHOLDER: Risk assessment is important to ensure we are making tools available to members in a responsible fashion. Please make every effort to do a reasonable risk assessment. If there is a safety incident with the tool, please redo a risk assessment and add it to the table.

| Ref / ID | Pre-Mitigation | Mitigations / Warnings / Remedies | Post Mitigation | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Risk | Risk Severity | Risk Likelyhood | Risk Level | Risk Severity | Risk Likelyhood | Risk Level | Acceptable to Proceed | ||

| 0001 | Death | Severe | Possible | 15 | Induction to train users in correct usage. | Severe | Very Unlikely | 5 | Yes |

| 0002 | Electric Shock | Major | Unlikely | 8 | Induction to train users in correct usage. Ensure power cables are properly connected and off the floor. Cables are tested and tagged and inspected for damage. | Minor | Very Unlikely | 2 | Yes |

| 0003 | Noise | Moderate | Likely | 12 | Train users to wear hearing protection. | Insignificant | Unlikely | 2 | Yes |

| 0004 | Tripping Hazard | Moderate | Possible | 9 | Train users to maintain a clean working area. Keep all cables off the ground and secured out of the way. | Insignificant | Unlikely | 2 | Yes |

| 0005 | Insufficient Lighting | Minor | Possible | 6 | Turn on shop lights. Open metal-shop doors for natural lighting. | Insignificant | Unlikely | 2 | Yes |

| 0006 | Entanglement | Major | Possible | 12 | Induction to train users in correct usage. Remove any possible entanglement items such as long sleeves, gloves, watches, jewellery, etc. Tie back long hair. | Minor | Unlikely | 4 | Yes |

| 0007 | Impact Injury | Major | Possible | 12 | Induction to train users in correct usage. Train users in correct use of the chuck/fixture plate as per the induction. Train users in chuck key discipline (never leave the chuck key in while performing another task). Train users to remove the chuck key before engaging the spindle motor. Train users in appropriate use of tailstock support. Require use of appropriate PPE. | Minor | Unlikely | 4 | Yes |

| 0008 | Laceration/Dismemberment | Major | Possible | 12 | Induction to train users in correct usage. Train users to keep clear of the cutting tool and the part. Require that the cutting tool is securely fixed (in the quick change tool-post or tail-stock). Require use of appropriate PPE. | Minor | Unlikely | 4 | Yes |

| 0009 | Burn from workpiece | Moderate | Possible | 9 | Induction to train users in correct usage. Allow parts to cool after cutting. Train users to ensure adequate coolant is used. Require assessing workpiece temperature before handling. | Insignificant | Unlikely | 2 | Yes |

| 0010 | Dust Inhalation - Low-hazard materials | Moderate | Likely | 12 | Induction to train users in correct usage. Require use of appropriate PPE. | Minor | Possible | 6 | Yes |

| 0011 | Dust Inhalation - Hazardous materials | Major | Likely | 16 | Induction to train users in correct usage. Restrict allowed grinding materals. | Insignificant | Unlikely | 2 | Yes |

Decision Register

PLACEHOLDER: A decision register is for general documentation when some decision is made regarding the tool. To change its location, mode of operation, to buy an accessory, to replace something, to change how it operates etc. Delete this line.

| Ref / ID | Decision Details | Impact | Proposed Date | Proposed By | Status | Approved By | Date | Resulting Actions and Comments |

|---|

- tools/metalshop/linisher

- Last modified: 7 months ago

- by

capella_ben

capella_ben