Welder, TIG - SWS Alumtig 200

| Aliases | |

| Other References | |

| Official Maintainer |

Current Status

Working

Machine is working as expected.

Usage

This machine requires induction to use.

Book an induction in Eventbrite.

https://www.eventbrite.com/cc/metalshop-inductions-804979

Personal Protective Equipment

| Required |  | Enclosed shoes are required, no open sandals, thongs etc |

| Required |  | Wear a welding helmet while welding |

| Recommended |  | We recommend the use of a respirator when welding fumes are generated |

| Recommended |  | Wear heat-resistant welding gloves when welding |

| Recommended |  | Wear flame retardant clothing while welding |

Machine Specifications

| Name | Value |

|---|---|

| Processes | HF TIG AC/DC (GTAW-AC/DC), LIFT TIG AC/DC (GTAW-AC/DC), Pulsed TIG (GTAW-P), Stick AC/DC (MMA) |

| Current Type | AC/DC |

| Weldable Metals | Aluminum, Mild Steel, Stainless Steel, Specialty Metals |

| Duty Cycle 40°C AMB (TIG/MMA) | 25% @ 200A, 100% @ 100A |

| Duty Cycle 25°C AMB (TIG/MMA) | 40% @ 200A, 100% @ 140A |

| Welding Current Range (TIG/MMA) | 10-200 Amps |

| Arc Ignition (TIG) | HF, Lift TIG |

| AC Frequency (TIG) | 10-200Hz |

| AC Balance (TIG) | 50-98% |

| Adjustable Parameters (TIG) | Pre-Flow, Post-Flow / Start-Amps, End-Amps / Upslope, Downslope |

| Pulse Peak Amps (TIG) | 10-200 Amps |

| Pulse Time On (TIG) | 10-90% |

| Pulse Frequency (TIG) | 1-500Hz |

| Pulse Base Amps (TIG) | 20-50% |

| Hot Start (MMA) | 0-60 Amps |

| Arc Force (MMA) | 0-99% |

Documents

Manufacturer/Supplier

Manufacturer

Machine is no longer available for sale or supported by supplier.

Known Identical Models

- None

Known Issues

| Date | Description | Workaround | Proposed Remediation |

|---|---|---|---|

Modifications / Repair History

| Date | Modified By | Description | Remediation | Cost |

|---|---|---|---|---|

Accessories

| Image | Category | Accessory Name & Notes | Location | Buy from |

|---|---|---|---|---|

| PLACEHOLDER Image, 100 width | Electrode Holder | TIG Torch Use for TIG Welding | Hung on TIG welding stand | |

| PLACEHOLDER Image, 100 width | Electrode Holder | Stick Electrode Holder Use for stick Welding | Hung on TIG welding stand |

Consumables & Running Costs

| Image | Category | Accessory Name & Notes | Location | Buy from |

|---|---|---|---|---|

| Torch Parts | Collets 1.6mm, 2.4mm & 3.2mm Copper collets used to hold tungsten electrode | Total Tools 1.6mm 2.4mm 3.2mm |

|

| Torch Parts | Collet Bodies 1.6mm, 2.4mm & 3.2mm Copper collet body used to house collets | Total Tools 1.6mm 2.4mm 3.2mm |

|

| Welding Gas | Argon Gas Inert gas used for TIG welding | Tied to TIG welding stand | |

| Torch Parts |

Cups | Stored inside TIG kit located in welding cabinet. | Hampdon #6 Cups #8 Cups #10 Cups |

Maintenance

| Interval | Task |

|---|---|

| Quarterly | Check condition of electrical cables and gas lines. |

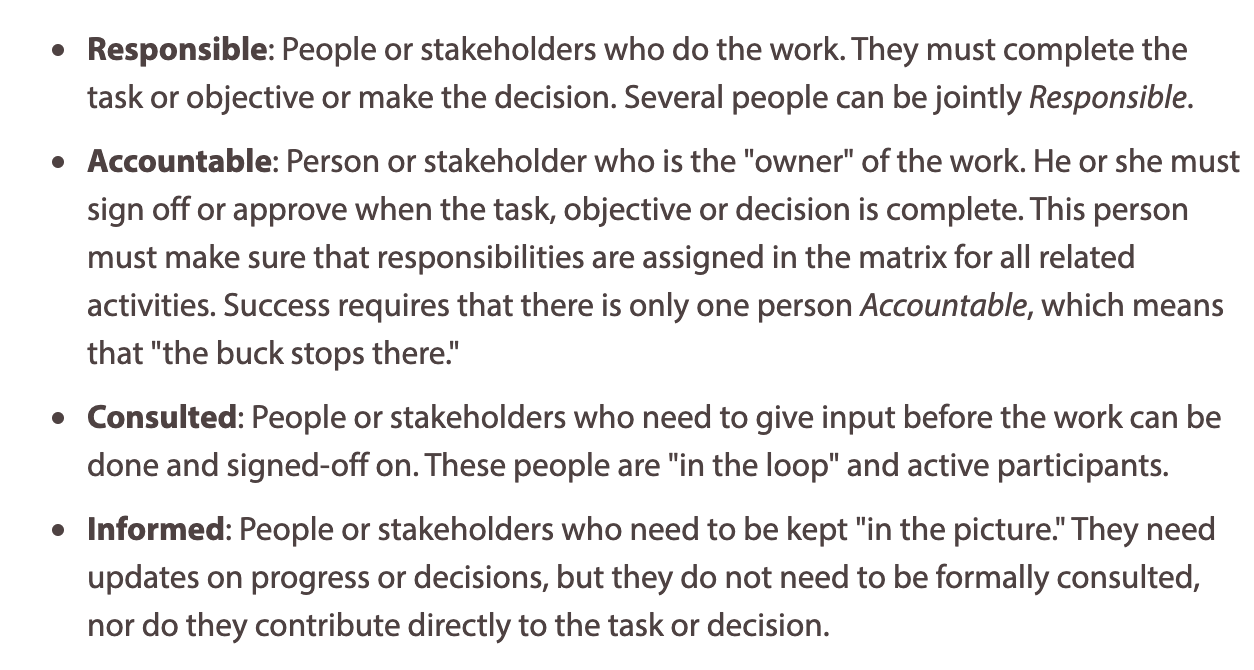

RACI

| Task / Action | Executive | Cause Leader Cause Team | Named Maintainer | Trainers | Cause | Membership | Implementer |

|---|---|---|---|---|---|---|---|

| Modification and Repairs | - | AC | C | I | I | I | R |

| Induction changes | C | RACI | RC | I | I | I | R |

| Replace argon cylinder | - | RACI | RC | I | I | I | R |

| Purchase approved consumables | - | RACI | RC | I | I | I | R |

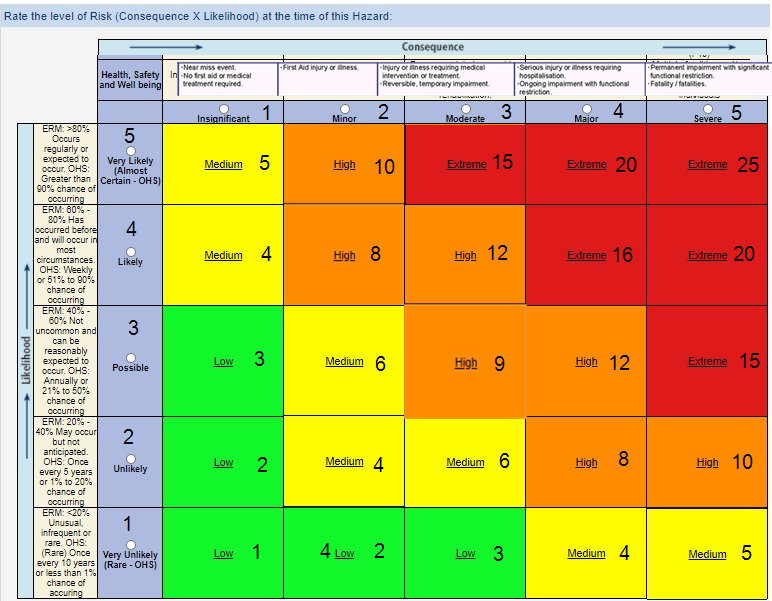

Risk Matrix and Mitigation

| Ref / ID | Pre-Mitigation | Mitigations / Warnings / Remedies | Post Mitigation | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Risk | Risk Severity | Risk Likelyhood | Risk Level | Risk Severity | Risk Likelyhood | Risk Level | Acceptable to Proceed | ||

| 0001 | Death | Severe | Possible | 15 | Induction to train users in correct usage. | Severe | Very Unlikely | 5 | Yes |

| 0002 | Electric Shock | Major | Unlikely | 8 | Induction to train users in correct usage. Ensure power cables are properly connected and off the floor. Cables are tested and tagged and inspected for damage. | Minor | Very Unlikely | 2 | Yes |

| 0003 | Noise | Moderate | Likely | 12 | Train users to wear hearing protection. | Insignificant | Unlikely | 2 | Yes |

| 0004 | Tripping Hazard | Moderate | Possible | 9 | Train users to maintain a clean working area. Keep all cables off the ground and secured out of the way. | Insignificant | Unlikely | 2 | Yes |

| 0005 | Insufficient Lighting | Minor | Possible | 6 | Turn on shop lights. Open metal-shop doors for natural lighting. | Insignificant | Unlikely | 2 | Yes |

| 0006 | Fumes | Major | Likely | 16 | Induction to train users in correct usage. Open metal-shop door to allow ventilation. Fans are provided top assist in ventilation. Require appropriate respiratory protection. Unauthorised access into welding area is prohibited. Other metal-shop users are informed that welding is in progress. | Minor | Possible | 6 | Yes |

| 0007 | Ejection of Sparks and Materials | Major | Likely | 16 | Induction to train users in correct usage. Require aappropriate welding shield with suitable eye protection is provided and worn. Screens are provided around the work area and are required to be used. Unauthorised access into welding area is prohibited. Other metal-shop users are informed that welding is in progress. | Minor | Possible | 6 | Yes |

| 0008 | Welding Flash / Eye Damage | Major | Likely | 16 | Induction to train users in correct usage. Appropriate welding shield with suitable eye protection is provided and worn. Screens are provided around the work area and are required to be used. Unauthorised access into welding area is prohibited. Other metal-shop users are informed that welding is in progress. | Minor | Possible | 6 | Yes |

| 0009 | Contact with Hot Parts | Major | Likely | 16 | Induction to train users in correct usage. Require use of appropriate PPE. Suitable how work gloves are provided and required to be worn. | Minor | Unlikely | 4 | Yes |

Decision Register

| Ref / ID | Decision Details | Impact | Proposed Date | Proposed By | Status | Approved By | Date | Resulting Actions and Comments |

|---|---|---|---|---|---|---|---|---|

| 0000 | Purchase welding masks & gloves to replace old ones. | Encourages use of proper PPE by having good quality equipment readily available. Reduces barrier to members who do not own welding PPE. | 29/12/2020 | Ryan Marple | Pending Approval | General Meeting | 12/01/2021 |

- tools/metalshop/welder_tig200p_vrd

- Last modified: 3 years ago

- by

capella_ben

capella_ben