OptiTurn TU3008G Metal Lathe

| Aliases | “Metal Lathe” |

| Other References | |

| Official Maintainer | Ben Jackson |

Current Status

Working

Machine is working as expected.

Usage

This machine requires induction to use.

To get an induction you must first review these videos. You must do this BEFORE attending the in-person induction (booked via event bright).

Safety: https://www.youtube.com/watch?v=0X1nZwOZH6M

Changing the Chuck: https://www.youtube.com/watch?v=K0pwJzHfJ50 Notes:

We have only 3 cam locks on out lathes. Stoning the chuck is not necessary. Keeping the precisions surfaces free of chis is essential. We use plywood instead of a block to protect the ways. Waxing of the chuck is not necessary.

Skills - Blondihacks: https://www.youtube.com/watch?v=H6Dnmd3lDzA&list=PLY67-4BrEae9Ad91LPRIhcLJM9fO-HJyN Only the following videos are mandatory:

1: Theory 2: Tool Bits 3: Facing 4: Tail Support 5: Turning

It is recommended to watch the entire series.

To enroll for an induction please go to Eventbrite.

At this in-person induction we will review how our machines work and have you perform a few simple operations on the lathe.

Usage

Learning

Recommended learning resources:

Recommended PPE

| Required |  | Always wear AS/NZS 1337.1 compliant safety glasses while operating this machine. |

| Required |  | Enclosed shoes are required, no open sandals, thongs etc |

| Required |  | Restrain hair while operating machine |

| Prohibited |  | Loose clothing and jewellery not to be worn while operating this machine. |

| Recommended |  | We recommend hearing protection. |

| Warning |  | Entanglement hazard present while wearing gloves. |

| Maintenance |  | Disconnect power to the machine before performing maintenance, including wheel changes |

Machine Specifications

PLACEHOLDER: Please fill out this table with all relevant machine specifications. The manufacturers website usually gives a good list. Delete this line.

| Name | Value |

|---|---|

| Attribute A | 305mm |

| Attribute B | 1600 mm x 270 mm |

| Attribute C | 3.0 hp |

Documents

PLACEHOLDER: Please copy the two WRAP blocks below for each file you upload relevant to this machine. This should be the manual at a minimum. Delete this line.

Manufacturer

PLACEHOLDER: Document the manufacturer, things like contact person names, emails, phone numbers, product urls etc. Document the reseller we bought from, and any other sources for similar things. Delete this line.

Manufacturer

- E sales@example.com

- P 00 0000 0000

Reseller

- Mr. Re seller

- Reseller Agencies

- E sales@reseller.com

- M 0000 000 000

Known Identical Models

- Links to other machines that are a rebrand or similar

Known Issues

| Date | Description | Workaround | Proposed Remediation |

|---|---|---|---|

| 01/01/2020 | PLACEHOLDER Describe the problem | PLACEHOLDER Describe the workaround currently in place | Placeholder Describe a proposed fix or solution |

Modifications / Repair History

| Date | Modified By | Description | Remediation | Cost |

|---|---|---|---|---|

| 01/01/2020 | PLACEHOLDER NAME | PLACEHOLDER Describe what happened | PLACEHOLDER Describe how it was fixed or modified | PLACEHOLDER document the cost of the change |

Accessories

| Image | Category | Accessory Name & Notes | Location | Buy from |

|---|---|---|---|---|

| PLACEHOLDER Image, 100 width | PLACEHOLDER Category of accessory | PLACEHOLDER Accessory Name PLACEHOLDER Description and usage notes for accessory | PLACEHOLDER Describe location of accessory | PLACEHOLDER Link to where it was bought from |

Consumables & Running Costs

| Image | Category | Accessory Name & Notes | Location | Buy from |

|---|---|---|---|---|

| PLACEHOLDER Image, 100 width | PLACEHOLDER Category of consumable | PLACEHOLDER Consumable Name PLACEHOLDER Consumable description and usage | PLACEHOLDER Description of where the consumable is stored | PLACEHOLDER Link to where it can be bought |

Maintenance

| Interval | Task |

|---|---|

| Each Use/Daily | General lubrication via the oiler points on the carriage and tailstock. See image below. |

| Monthly | Check oil levels in headstock, gearbox and apron. Refer to manual page 24. |

| Monthly | Grease gear train. |

| Monthly | Inspect and adjust the drive belt. Refer to manual page 22. |

| Annually | Adjust Slide Ways and Cross-Slide nut. Refer to manual page 23. |

| Annually | Change the oil in the headstock, gearbox and apron. Refer to manual page 24. |

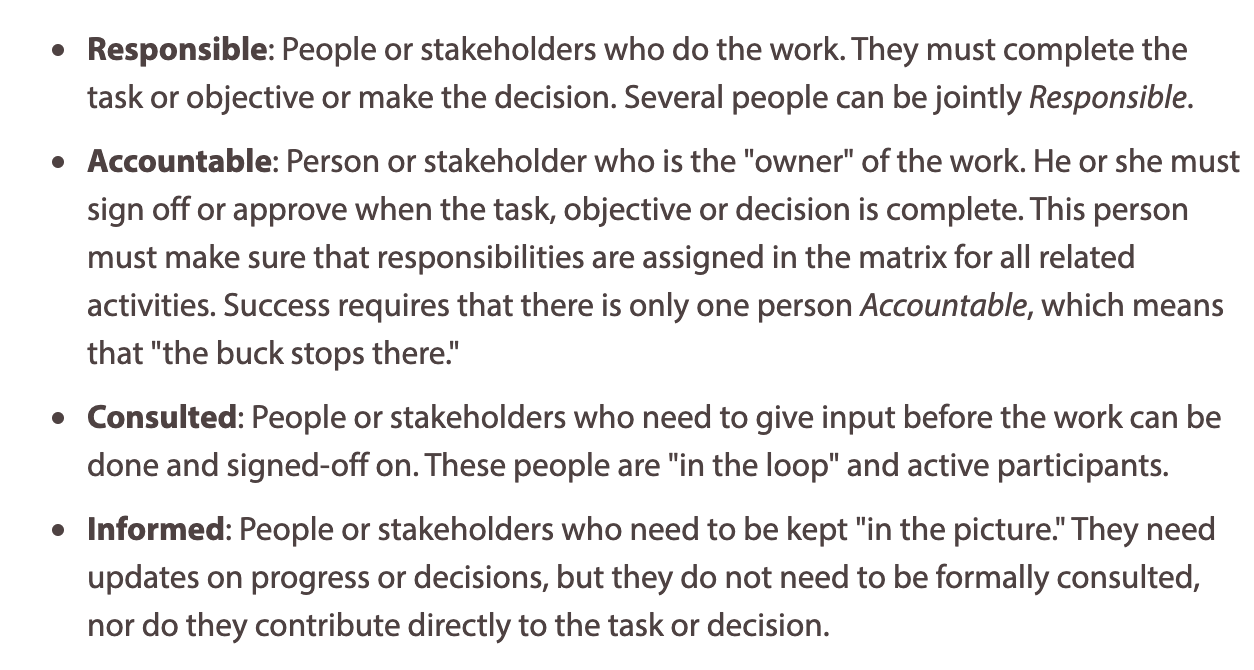

RACI

| Task / Action | Executive | Cause Leader Cause Team | Named Maintainer | Trainers | Cause | Membership | Implementer |

|---|---|---|---|---|---|---|---|

| Modification and Repairs | - | AC | C | I | I | I | R |

| Induction changes | C | RACI | RC | I | I | I | R |

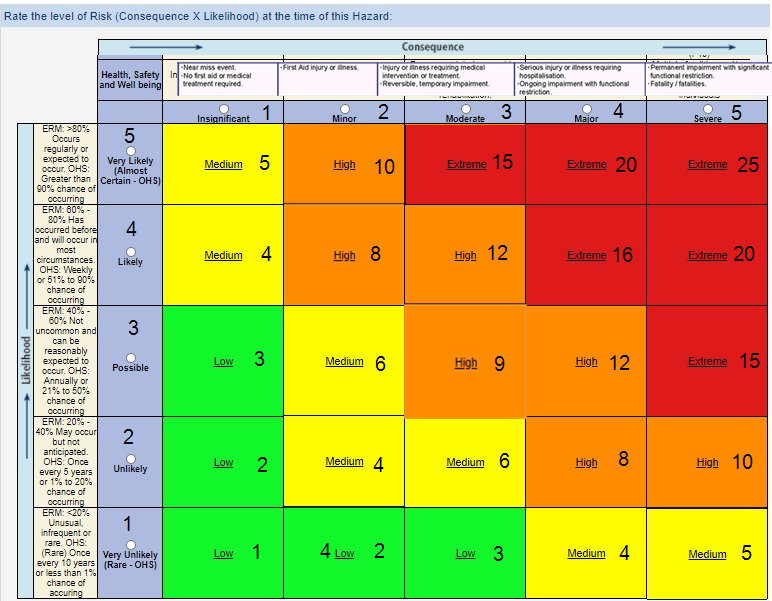

Risk Matrix and Mitigation

| Ref / ID | Pre-Mitigation | Mitigations / Warnings / Remedies | Post Mitigation | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Risk | Risk Severity | Risk Likelyhood | Risk Level | Risk Severity | Risk Likelyhood | Risk Level | Acceptable to Proceed | ||

| 0001 | Death | Severe | Possible | 15 | Induction to train users in correct usage. | Severe | Very Unlikely | 5 | Yes |

| 0002 | Electric Shock | Major | Unlikely | 8 | Induction to train users in correct usage. Ensure power cables are properly connected and off the floor. Cables are tested and tagged and inspected for damage. | Minor | Very Unlikely | 2 | Yes |

| 0003 | Noise | Moderate | Likely | 12 | Train users to wear hearing protection. | Insignificant | Unlikely | 2 | Yes |

| 0004 | Tripping Hazard | Moderate | Possible | 9 | Train users to maintain a clean working area. Keep all cables off the ground and secured out of the way. | Insignificant | Unlikely | 2 | Yes |

| 0005 | Insufficient Lighting | Minor | Possible | 6 | Turn on shop lights. Open metal-shop doors for natural lighting. | Insignificant | Unlikely | 2 | Yes |

| 0006 | Entanglement | Major | Possible | 12 | Induction to train users in correct usage. Remove any possible entanglement items such as long sleeves, gloves, watches, jewellery, etc. Tie back long hair. | Minor | Unlikely | 4 | Yes |

| 0007 | Impact Injury | Major | Possible | 12 | Induction to train users in correct usage. Train users in correct use of the chuck/fixture plate as per the induction. Train users in chuck key discipline (never leave the chuck key in while performing another task). Train users to remove the chuck key before engaging the spindle motor. Train users in appropriate use of tailstock support. Require use of appropriate PPE. | Minor | Unlikely | 4 | Yes |

| 0008 | Slip | Major | Possible | 12 | Induction to train users in correct usage. Train users in correct use of coolant to avoid spilling on the floor. | Minor | Unlikely | 4 | Yes |

| 0009 | Respiratory/Skin Irritation | Moderate | Unlikely | 6 | Induction to train users in correct usage. Train users in the risks related to metalworking fluids. | Minor | Unlikely | 4 | Yes |

| 0010 | Inhaliation of Fumes | Moderate | Possible | 9 | Induction to train users in correct usage. Open metal-shop door to allow ventilation. Fans are provided top assist in ventilation. Train users to use the appropriate type and volume of coolant. Require use of appropriate PPE. | Minor | Unlikely | 4 | Yes |

| 0011 | Laceration/Dismemberment | Major | Possible | 12 | Induction to train users in correct usage. Train users to keep clear of the cutting tool and the part. Require that the cutting tool is securely fixed (in the quick change tool-post or tail-stock). Require use of appropriate PPE. | Minor | Unlikely | 4 | Yes |

| 0012 | Burn from workpiece | Moderate | Possible | 9 | Induction to train users in correct usage. Allow parts to cool after cutting. Train users to ensure adequate coolant is used. Require assessing workpiece temperature before handling. | Insignificant | Unlikely | 2 | Yes |

Decision Register

PLACEHOLDER: A decision register is for general documentation when some decision is made regarding the tool. To change its location, mode of operation, to buy an accessory, to replace something, to change how it operates etc. Delete this line.

| Ref / ID | Decision Details | Impact | Proposed Date | Proposed By | Status | Approved By | Date | Resulting Actions and Comments |

|---|---|---|---|---|---|---|---|---|

| 0000 | Example decision | Provides an example | 08/08/20 | JH | Approved | JH | 08/08/20 | A line was put in the register |

- tools/metalshop/metal_lathe

- Last modified: 99 minutes ago

- by

capella_ben

capella_ben