Saw, Cold Cut - MEP Scorpio 300

| Aliases | Cold Cut Saw |

| Other References | |

| Official Maintainer | TBA |

Current Status

Commissioning

The machine is in the process of being re-commissioned at the new site.

Usage

This machine requires induction to use.

Book an induction in Eventbrite.

https://www.eventbrite.com/cc/metalshop-inductions-804979

This machine is a part of the Drill Press, Linishers and Vertical bandsaw induction.

Guidelines

- Ensure that there is coolant in the tank and that the coolant is flowing when you turn it on.

- If there is no coolant flow ensure that there is enough coolant in the tank. Add more if necessary without overflowing the tank.

- Clamp the work in the vice securely.

- Use the slow speed (1) for cutting ferrous materials and fast (2) for non-ferrous materials.

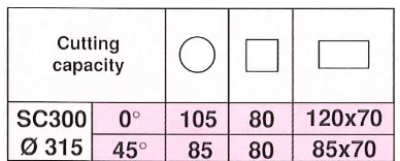

Cutting Capacity

Blade Removal

- Turn off the power to the tool

- Remove the thumbscrew for the blade guard mechanism. This is to allow you to hold the blade later.

- Use the large socket (on the shelf under the tool) to undo the large nut holding the blade on. This is a REVERSE thread!

- Remove the nut and mounting plate and remove the blade. Note: the blade may be very sharp!

- Do not loose the nut and plate. If not replacing the blade then re-mount these to the tool.

- Replace the large socket to the shelf under the tool!

Note: The internal hex bolt in the middle of the spindle need not be touched while removing the blade. This is for the clutch mechanism.

Recommended PPE

| Required |  | Always wear AS/NZS 1337.1 compliant safety glasses while operating this machine. |

| Required |  | Enclosed shoes are required, no open sandals, thongs etc |

| Required |  | Restrain hair while operating machine |

| Prohibited |  | Loose clothing and jewellery not to be worn while operating this machine. |

| Recommended |  | We recommend hearing protection. |

| Warning |  | Entanglement hazard present while wearing gloves. |

| Maintenance |  | Disconnect power to the machine before performing maintenance, including wheel changes |

Machine Specifications

| Name | Value |

|---|---|

| Blade Size | 300×2.5×32 |

| Speeds | 30/60 rpm |

| Max Vice Width | 145mm |

Documents

Manufacturer

Manufacturer

MEP Saws However this saw is from the 1980's and is not on their web site. The Falcon series is the modern equivalent.

Known Issues

| Date | Description | Workaround | Proposed Remediation |

|---|---|---|---|

| 9/08/2022 | Blunt blades | There is no workaround at this time | The blades are currently out for sharpening. |

Modifications / Repair History

| Date | Modified By | Description | Remediation | Cost |

|---|---|---|---|---|

| 09/08/2022 | Ben Jackson | Loss of coolant flow | Coolant was blocked by the swivel joint. This is not required, not is the valve as we always want to use full flow. These have been removed and the hose connected directly to the nozzle. | $0 |

Accessories

| Image | Category | Accessory Name & Notes | Location | Buy from |

|---|---|---|---|---|

| Accessory | Anti-burr Device | On the shelf under the saw. |

Consumables & Running Costs

| Image | Category | Accessory Name & Notes | Location | Buy from |

|---|---|---|---|---|

| Blade | Replacement Blade Replacement HSS blade. | On the shelf under the saw. |

Maintenance

| Interval | Task |

|---|---|

| Monthly | Clean chip tray to ensure quick return of coolant |

| Annual | Sharpen Blades |

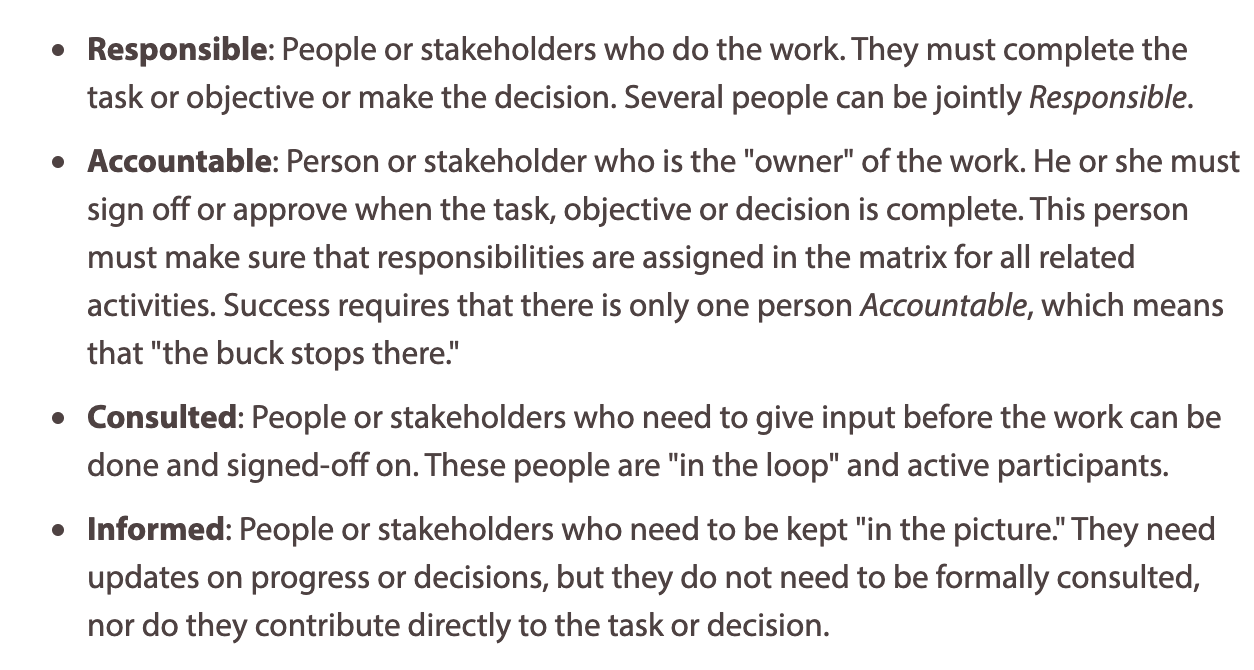

RACI

| Task / Action | Executive | Cause Leader Cause Team | Named Maintainer | Trainers | Cause | Membership | Implementer |

|---|---|---|---|---|---|---|---|

| Modification and Repairs | - | AC | C | I | I | I | R |

| Induction changes | C | RACI | RC | I | I | I | R |

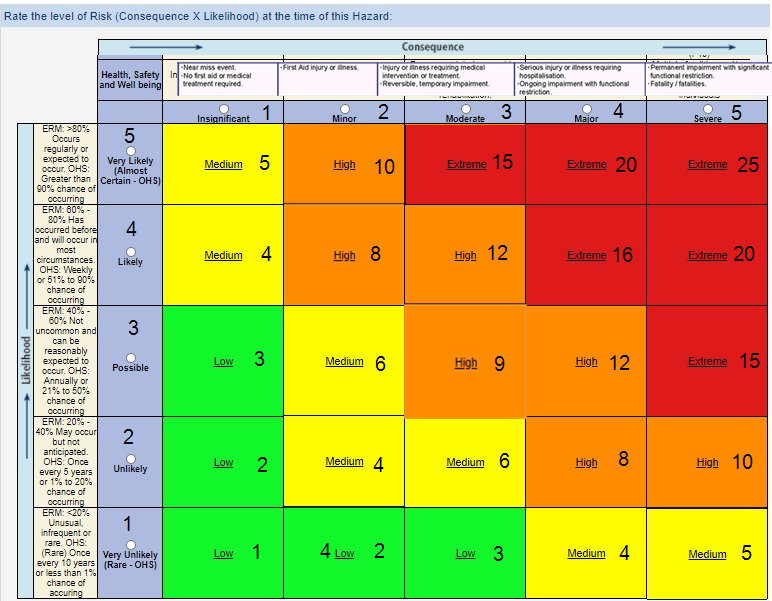

Risk Matrix and Mitigation

| Ref / ID | Pre-Mitigation | Mitigations / Warnings / Remedies | Post Mitigation | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Risk | Risk Severity | Risk Likelyhood | Risk Level | Risk Severity | Risk Likelyhood | Risk Level | Acceptable to Proceed | ||

| 0001 | Death | Severe | Possible | 15 | Induction to train users in correct usage. | Severe | Very Unlikely | 5 | Yes |

| 0002 | Electric Shock | Major | Unlikely | 8 | Induction to train users in correct usage. Ensure power cables are properly connected and off the floor. Cables are tested and tagged and inspected for damage. | Minor | Very Unlikely | 2 | Yes |

| 0003 | Noise | Moderate | Likely | 12 | Train users to wear hearing protection. | Insignificant | Unlikely | 2 | Yes |

| 0004 | Tripping Hazard | Moderate | Possible | 9 | Train users to maintain a clean working area. Keep all cables off the ground and secured out of the way. | Insignificant | Unlikely | 2 | Yes |

| 0005 | Insufficient Lighting | Minor | Possible | 6 | Turn on shop lights. Open metal-shop doors for natural lighting. | Insignificant | Unlikely | 2 | Yes |

| 0006 | Entanglement | Major | Possible | 12 | Induction to train users in correct usage. Remove any possible entanglement items such as long sleeves, gloves, watches, jewellery, etc. Tie back long hair. | Minor | Unlikely | 4 | Yes |

| 0007 | Impact Injury | Major | Possible | 12 | Induction to train users in correct usage. Train users in correct use of the chuck/fixture plate as per the induction. Train users in chuck key discipline (never leave the chuck key in while performing another task). Train users to remove the chuck key before engaging the spindle motor. Train users in appropriate use of tailstock support. Require use of appropriate PPE. | Minor | Unlikely | 4 | Yes |

| 0008 | Slip | Major | Possible | 12 | Induction to train users in correct usage. Train users in correct use of coolant to avoid spilling on the floor. | Minor | Unlikely | 4 | Yes |

| 0010 | Respiratory/Skin Irritation | Moderate | Unlikely | 6 | Induction to train users in correct usage. Train users in the risks related to metalworking fluids. | Minor | Unlikely | 4 | Yes |

| 0011 | Inhaliation of Fumes | Moderate | Possible | 9 | Induction to train users in correct usage. Open metal-shop door to allow ventilation. Fans are provided top assist in ventilation. Train users to use the appropriate type and volume of coolant. Require use of appropriate PPE. | Minor | Unlikely | 4 | Yes |

| 0012 | Laceration/Dismemberment | Major | Possible | 12 | Induction to train users in correct usage. Train users to keep clear of the cutting tool and the part. Require that the cutting tool is securely fixed (in the quick change tool-post or tail-stock). Require use of appropriate PPE. | Minor | Unlikely | 4 | Yes |

| 0013 | Burn from workpiece | Moderate | Possible | 9 | Induction to train users in correct usage. Allow parts to cool after cutting. Train users to ensure adequate coolant is used. Require assessing workpiece temperature before handling. | Insignificant | Unlikely | 2 | Yes |

| 0014 | Crushing | Severe | Unlikely | 10 | Induction to train users in correct usage. | Minor | Unlikely | 4 | Yes |

Decision Register

| Ref / ID | Decision Details | Impact | Proposed Date | Proposed By | Status | Approved By | Date | Resulting Actions and Comments |

|---|---|---|---|---|---|---|---|---|

- tools/metalshop/saw_cold_cut_-_mep_scorpio_300

- Last modified: 7 months ago

- by

capella_ben

capella_ben